Sign up for our newsletter!

Your data will be handled in compliance with our privacy policy.

Your data will be handled in compliance with our privacy policy.

Smoltek Hydrogen has developed a new material that solves the major technical challenge that threatens to halt the fast-growing industry for green hydrogen produced by intermittent energy sources, such as solar and wind power. With the groundbreaking nanomaterial, the use of iridium (catalysts) in PEM electrolyzers can be reduced to levels that make large-scale hydrogen production profitable.

Green hydrogen, produced from fossil-free electricity is considered, both within the EU and globally, to be a key technology to manage the green transition. Currently, there are no other fossil-free alternatives for many industrial and shipping areas. Green hydrogen has the potential to become the leading solution for fossil-free steel production and heavy ocean freight.

When producing green hydrogen in large solar or wind farms, it is crucial to be able to quickly start and stop production. This process requires the specific PEM electrolysis technology, where the expensive and rare metal iridium splits water into hydrogen and oxygen. Unfortunately, the lack of available iridium risks making mass production of PEM electrolyzers unprofitable. This is due to today’s overuse of iridium, as well as the fact that the price of iridium is forecast to rise significantly in the coming years.

Smoltek’s nanomaterial – proven technology lead and a clear path to commercial manufacturing

Smoltek Hydrogen has developed a nanomaterial that has been proven to work well in long-term studies, and the company has a clear path to reach the goal of 0.1 mg of iridium per square centimeter, which Smoltek as well as the leading institute Fraunhofer consider to be the level at which large-scale manufacturing of PEM electrolyzers becomes commercially profitable. This is probably the only industrially verified solution that is able to reach this tipping point.

To capitalize on this head start, Smoltek Hydrogen is now seeking financially strong partners to finance the remaining development and commercialization of the nanomaterial, including scale-up of production capacity, and create the conditions needed to reach its target of a 30% market share, corresponding to approx. 20 billion SEK in net sales in 2030. This process has been concretized with Smoltek’s ongoing bidding process for Smoltek Hydrogen, which is expected to take 6–12 months.

We have high ambitions as we are currently unique in providing a solution to a critical problem. Following the presentation of excellent long-term results, we have started to more firmly work towards becoming the electrolyzer manufacturers’ collaboration partner for the next generation of electrolyzers. The interest from leading players is strong even before we have actively started to reach out to the market, and discussions and tests are already underway with a number of leading companies. Our target is to reach a 30 percent market share in 2030 together with partners, which would correspond to a turnover of approximately 20 billion SEK. And even if the projected sales volume is large, a giant factory plant is not required. But it is urgent to start building a pilot plant, because time is short. For that reason, the ongoing bidding process is an important step on the way there.

Ellinor Ehrnberg, President of Smoltek Hydrogen

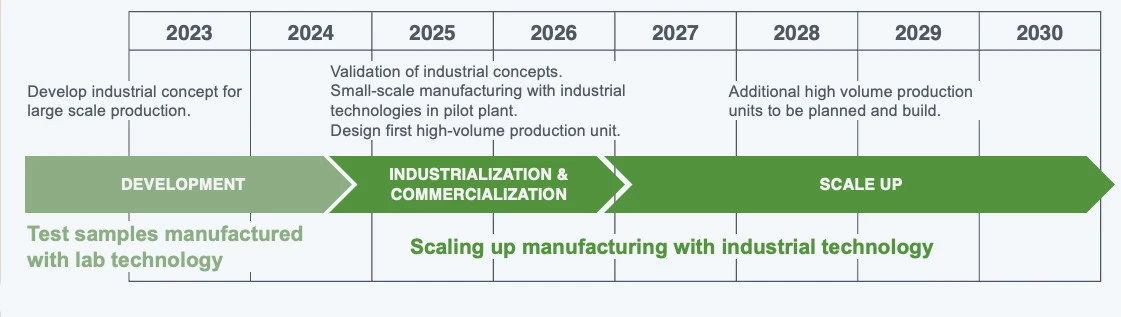

Plan for industrial production of the nanomaterial

During the next year, Smoltek Hydrogen plans to establish a pilot plant for small-scale industrial production to, together with customers, manufacture prototypes of new electrolyzers and, together with machine suppliers, be able to create the specifications for the first large-scale plant. There are several possible paths forward regarding volume production, but in a such a fast-growing industry it is not unusual to build up the business operations as an independent company, as an alternative to being part of a larger industrial structure.

Your data will be handled in compliance with our privacy policy.