Sign up for our newsletter!

Your data will be handled in compliance with our privacy policy.

Your data will be handled in compliance with our privacy policy.

Smoltek's CNF-MIM technology offers a competitive alternative to silicon capacitors for ultra-thin high-performance capacitors used in processors for mobile phones and computers. The next-generation capacitors, Gen-One, is planned to be completed by the end of 2024, matching competitors in performance with an exceptionally thin form factor. The strategic objective is to pair up with a financially strong partner for the industrialization and commercialization of the capacitors.

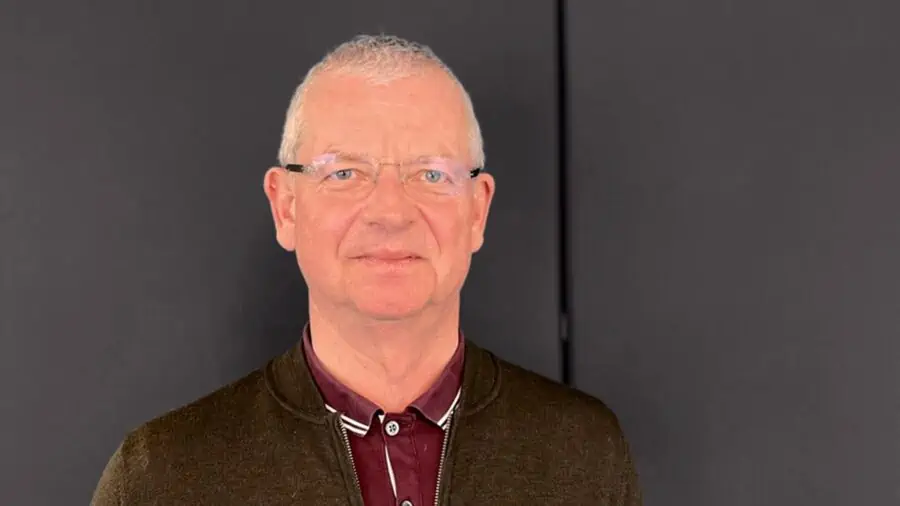

Interview with Philip Lessner, CTO of Yageo Group about the future of the capacitor industry, the market and technology needs for ultra-thin capacitors. And how CNF-MIM technology fits into this market.

This is a follow-up to last year's interview, about how the two companies were a perfect fit. Yageo remains interested in Smoltek's CNF-MIM capacitors and sees great potential for using CNF-MIM capacitors now and in the future.

Note: Extended version (15:54 mins) available on https://youtu.be/ad4ESm2AmEw.

Smotek Semi is taking the next step in the development of the CNF-MIM capacitor technology, in technical collaboration with Yageo. And the next generation – Gen-One is expected to deliver a fivefold increase in capacitance density compared to Gen-Zero.

In this interview, Farzan Ghavanini, CTO at Smotek, talks about how Smoltek Semi has developed a new technology generation of our CNF-MIM capacitor technology. The new generation, called Gen-Zero, is the foundation for achieving the goal of manufacturing different types of capacitors with very high capacitance density – by enabling high volumetric capacitance density.

Smotek Semi has developed a new technology generation of our CNF-MIM capacitor technology. The new generation, called Gen-Zero, is the foundation for achieving the goal of manufacturing different types of capacitors with very high capacitance density – by enabling high volumetric capacitance density.

Smoltek and Yageo have collaborated for a long time to enter into an agreement regarding the further development and commercialization of capacitors based on Smoltek's CNF-MIM technology. In December both parties announced the intention to enter into a license and service agreement. However, yesterday Yageo choose not to sign the agreement.

During the festive season, there is time for longreads. We, therefore, want to offer a text that goes beyond what we usually write here on the blog but is not entirely unrelated to what Smoltek does. This is the story of the origin of the capacitor. Happy reading!

Smoltek has the intention to sign a global exclusive license and services agreement for discrete and embedded capacitors with YAGEO Group. This would grant YAGEO a global, exclusive right to manufacture and sell capacitor products based on Smoltek's patent protected technology platform for ultra-thin carbon nanofiber capacitors (CNF-MIM).

Advanced nano- and microelectronics are at the core of tomorrow’s hardware engineering. At Smoltek we are pioneering carbon nanotechnology that enables manufacturing of the next-generation solutions for the semiconductor industry. Currently the focus is on a new type of carbon nanofiber-based capacitor that fits in the extremely miniaturized packaging architectures being developed by chip manufacturers.

Smoltek has produced a quarter million capacitors (without carbon nanofiber) and has begun producing a new batch (with carbon nanofiber). This is huge because it shows that our high-volume manufacturing process works. It is intended to be used to produce engineering samples. You could read about this in a press release. In this article, we unpack what this means.

Smoltek Semi has developed a process for manufacturing of engineering samples in high volumes. This process will now be tested for production of CNF-MIM engineering samples in high volumes, as the first trial-run of capacitor prototypes (without the patent protected carbon nanofibers) was successful.

Philip Lessner, CTO at YAGEO Group says in an interview that he and Yageo sees a lot of potential in Smotek's disruptive CNF-MIM capacitor technology for making capacitors in extremely small form factors.