Sign up for our newsletter!

Your data will be handled in compliance with our privacy policy.

Your data will be handled in compliance with our privacy policy.

In an age where environmental sustainability is of utter importance, it is crucial to find innovative solutions to reduce energy consumption and minimize our carbon footprint. One such solution is found in capacitors. These unassuming electronic components not only play an important role in various systems, but also offer significant environmental benefits. Albeit very small – if counted one by one.

Modern electronics demand increasingly compact and powerful capacitors, and the race for miniaturization has reached a critical juncture. While both Deep Trench Capacitors (DTC) and Carbon Nanofiber Metal-Insulator-Metal (CNF-MIM) capacitors are being developed for advanced applications requiring smaller size and higher capacitance density than conventional surface-mounted capacitors, DTC pushes the boundaries of what’s achievable with subtractive manufacturing, but is hitting fundamental physical limits. In contrast, Smoltek’s innovative CNF-MIM technology offers a revolutionary path forward, unrestricted by these constraints.

We are pleased to announce that the new zirconia based dielectric stack, previously reported to show 230% improvement in capacitance density, has now passed the 1,000-hour DC life test, a preliminary reliability test, carried out by capacitor manufacturer Yageo.

Dr. Farzan Ghavanini, CTO of Smoltek has been on a week-long business trip to Taiwan to visit some of our collaboration partners for CNF-MIM capacitors, among those ALD-company Skytech.

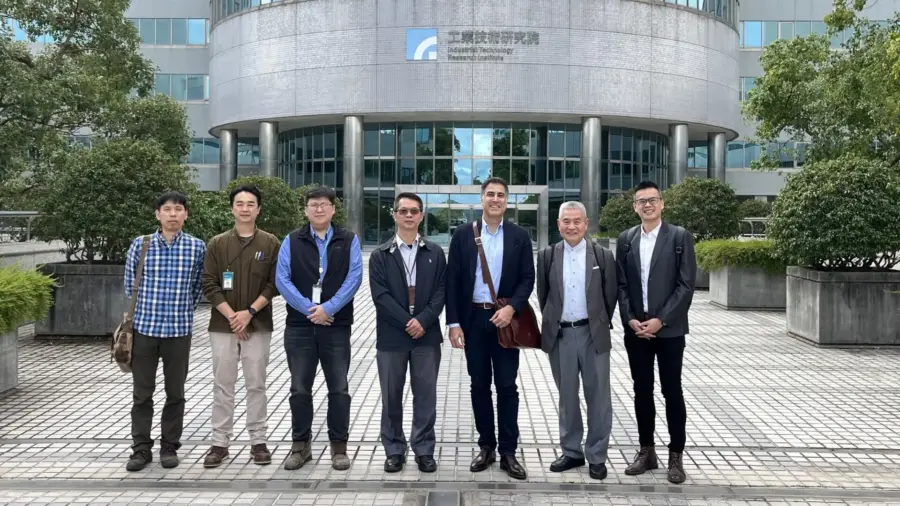

Smoltek recently visited its Taiwanese partner in advanced microelectronic packaging to discuss the specific requirements for next generations of Smoltek's CNF-MIM (Carbon Nanofiber-Metal Insulator-Metal) capacitors.

Smoltek Semi and Taiwanese Industrial Technology Research Institute (ITRI) are discussing a collaboration to set up a pilot line for fabrication of CNF-MIM capacitors in Taiwan as part of getting ready for mass production.

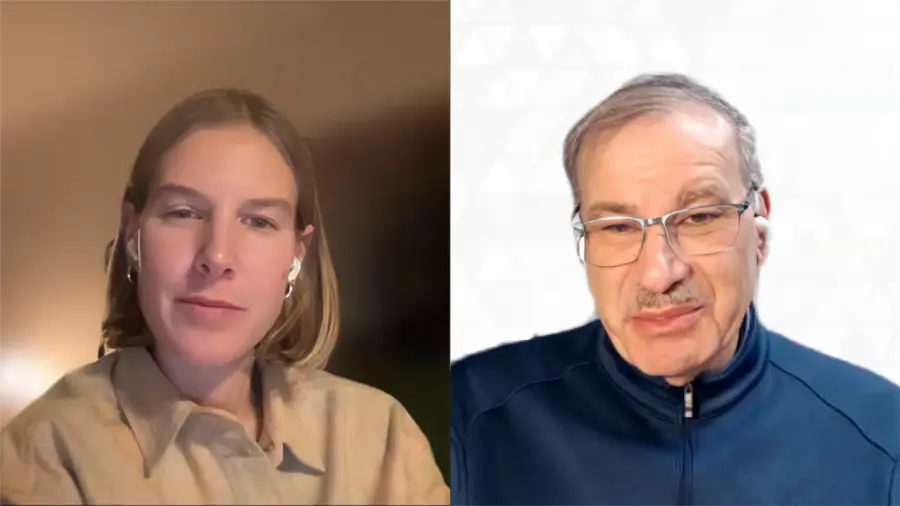

Interview with Philip Lessner, CTO of Yageo Group about the rapid development in the capacitor industry, the market evolvement and future technology needs for ultra-thin capacitors. And how CNF-MIM technology fits into this market. This is a follow-up to the interview from earlier this year. Yageo remains interested in Smoltek's CNF-MIM capacitors and sees great potential for using CNF-MIM capacitors in their customer offering.

The ultra-thin capacitor market is entering a new phase as major players like Murata and Samsung invest heavily in silicon-based solutions. In a recent interview, YAGEO Group's CTO Philip Lessner explains why Smoltek's CNF-MIM technology could offer superior advantages to silicon-based solutions in this rapidly growing market.

Smoltek Semi has developed a new process, known as zapping, that reduces the number of steps required to manufacture test capacitors.

Our innovative “zapping” method drastically reduces development time and costs, enabling us to advance CNF-MIM technology faster and making Smoltek Semi’s technology even more attractive to potential buyers. Read on to see how this new process strengthens our position and shortens our path to market.

Smoltek Semi has developed a new material for use in CNF-MIM capacitors. The new material increases capacitance by more than three times and reduces leakage current by 50 percent. In this article, we examine what this means and why it is good for shareholders and investors.

Smoltek Semi has spent the last nine months working intensively on a project to develop a new dielectric stack for the CNF-MIM capacitor technology resulting in a 230% boost in capacitance density.