Sign up for our newsletter!

Your data will be handled in compliance with our privacy policy.

Your data will be handled in compliance with our privacy policy.

In March 2022, we told the world we had ordered a machine. In October 2023, we announced that it is ready for delivery. But what kind of machine is it? What does it do? Why has it taken so long? Where will it be located? How will it be used? You will find the answers here.

Now it’s ready: Our machine for large-scale manufacturing of carbon nanofibers. You can read about this in a press release. But a press release says only so much. There is much more to say about “the machine,” as we call it. So buckle up, let’s talk about it.

First, you may wonder what kind of machine we are talking about.

If you ask our researchers and developers, it is a system consisting of a PECVD reactor chamber and tools for high-volume production.

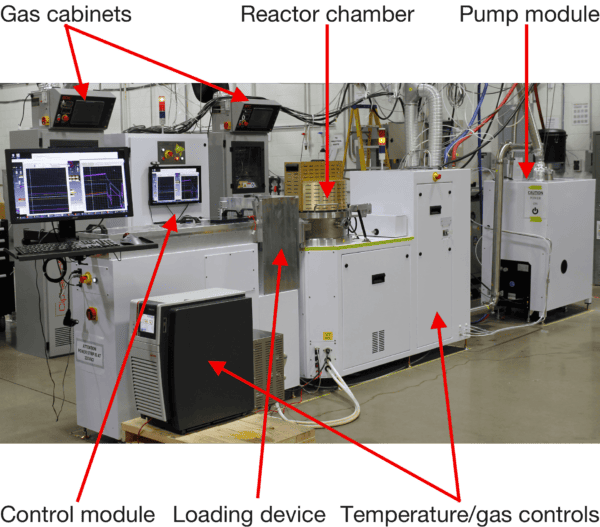

PECVD stands for Plasma Enhanced Chemical Vapor Deposition. The tools include a loading device, vacuum pumps, cabinets for gases, and a control module.

If you ask me, I would describe it as an oven for high-volume “baking” of carbon nanofibers on wafers and other substrates. (Wafers are silicon discs processed in several steps to create integrated circuits, commonly known as chips.)

The machine consists of several parts:

The reaction chamber is where the magic happens. It has valves to let a gaseous carbon compound in and out of the chamber. It has an electrode in the ceiling that creates plasma – free-floating electrons – that causes the gas to release the carbon atoms that build our carbon nanofibers. And it has a heating plate on which prepared wafers are placed.

The loading device puts the wafer into the reaction chamber and takes it out when finished. Loading is done automatically from a cartridge that holds 25 wafers. We use 8‑inch diameter wafers. This is the most common size in the industry.

The vacuum pumps evacuate the chamber of air so that we can control the process conditions and the samples are not contaminated by unwanted substances.

The gas cabinets are needed to store the gases going in and out of the reaction chamber.

The control module, the cherry on the cake, monitors and controls the whole process.

Altogether, the parts take up a floor space of more than 4.5 × 2 meters and weights more than 3.6 tons and. It’s a beast.

The reactor chamber is designed in close collaboration between the manufacturer and us, and it is custom-built to meet our specifications.

It contains several innovative technical solutions. Many things have been considered: material selection, mechanical design, compatibility with our patent-protected process, and more. And the control module software is specially designed for our machine.

So, it is no exaggeration to say that the machine is the only one of its kind. It is truly unique. It’s a beauty.

It took a year and half to build this machine. We knew it would take a long time for the machine to be finished when we placed the order in March 2022.

We anticipated that the manufacturer would have to make some tinkering here and there. It’s natural; you rarely get it one hundred percent right the first time you do something so complex. And one hundred percent right is what we demand. We can’t compromise on quality. So, it took a few iterations to meet our high standards.

The manufacturer, CVD Equipment Corporation in the US, is very professional and has done an outstanding job. We are delighted with the carbon nanofibers grown during the acceptance test.

Now, all that remains is to get the machine delivered.

But first, all parts must be CE marked, which means that the manufacturer declares that the parts comply with relevant EU legislation and can be brought into the European Economic Area (EEA). This work is ongoing at the time of writing.

After that, the machine has to be packed and shipped. It sounds more straightforward than it is. A custom-built machine requires custom packaging and special shipping. It isn’t an ordinary piece of equipment we have bought.

If everything goes as planned, the machine will be shipped around the turn of the year.

We plan to place the machine at a foundry we choose to work with. But we have not yet decided which one. So, for now, it will be stored at Chalmers University of Technology.

Why not set it up at Chalmers, where our older machines are already located, or another temporary location while waiting for the right partners to be chosen?

We have considered that but concluded that it is better to await the choice of a partner.

Remember, it’s a beast. It takes up a lot of space. Requires a lot of energy. And above all, it has to be in a clean room. There are no suitable places available for temporary use. We would have to pay for extensive rebuilding and installation work. Money that could be put to better use.

Once in place, the machine will be part of manufacturing CNF-MIM capacitors.

The throughput is one wafer each half hour. Each wafer contains 48,000 CNF-MIM capacitors. We plan to process 500 wafers per month. That’s 24 million capacitors per month. And that’s just the beginning. The machine can be built out to produce 10X more wafers, that is, 5,000 wafers per month.

We cannot do that volume with our current machine, which can produce far fewer capacitors per wafer, takes four times as long, and must be operated manually. The new machine is simply necessary for high-volume production of CNF-MIM capacitors.

The new machine is also scalable. We can expand it with several parallel reaction chambers to multiply the volume.

By the way, I lied to you at the beginning.

We don’t call it “the machine.” We call it “the high-volume machine,” or HVM for short. But it doesn’t sound as good as “the machine,” so I gave myself an artistic license to shorten the name. Sorry. Now, over to you. Head over to LinkedIn and tell us what more you would like to know about “the machine.”

Your data will be handled in compliance with our privacy policy.