Sign up for our newsletter!

Your data will be handled in compliance with our privacy policy.

Your data will be handled in compliance with our privacy policy.

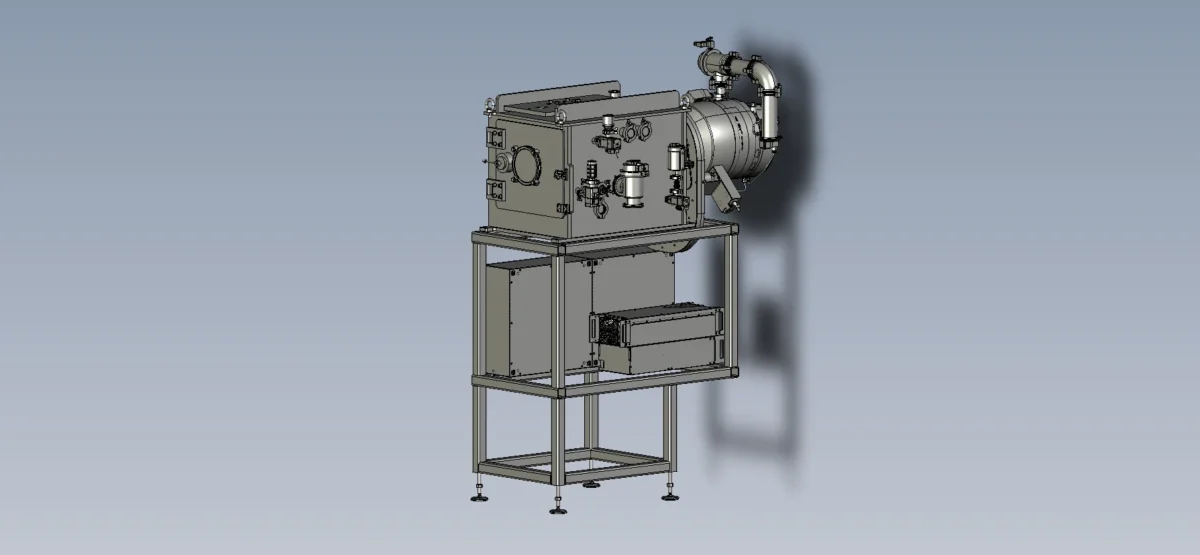

Smoltek Hydrogen and AGC Plasma Technology Solutions have finalized the design of a Prototype Coater for industrial growth of carbon nanofibers. The purpose with the tool is to verify that the nanofibers can be grown using a Plasma Enhanced Chemical Vapor Deposition (PECVD) technology from AGC. The technology is scalable and can be extended to be used for substrates of several square meters, for future mass production.

Smoltek Hydrogen is working on solving the biggest pain point of PEM electrolyzers – “The Iridium problem”. Iridium is needed as catalyst on the anode side in an electrolyzer cell. However, iridium is extremely expensive and most of all scarce and a limited resource, and the shortage of iridium is recognized as the single most severe threat towards scaling up PEM electrolyzers. For this reason, the hydrogen industry is eager to find a new, game-changing technology that can significantly reduce the iridium load.

Smoltek Hydrogen has a solution to this particular problem, by introducing an ultra-thin iridium coating on the porous transport layer side instead of the membrane, and where the surface area first has been enlarged by coating the surface with corrosion protected vertical carbon nanofibers.

Smoltek Hydrogen aims to reduce the iridium amount with 95% compared to today’s standard material (that uses ca 2.5 mg iridium/cm2), and has recently completed a 1,000 hour durability test with only 0.2 mg iridium/cm2 (Read about the test).

Manufacturing technologies to enable scale-up of PEM electrolyzers

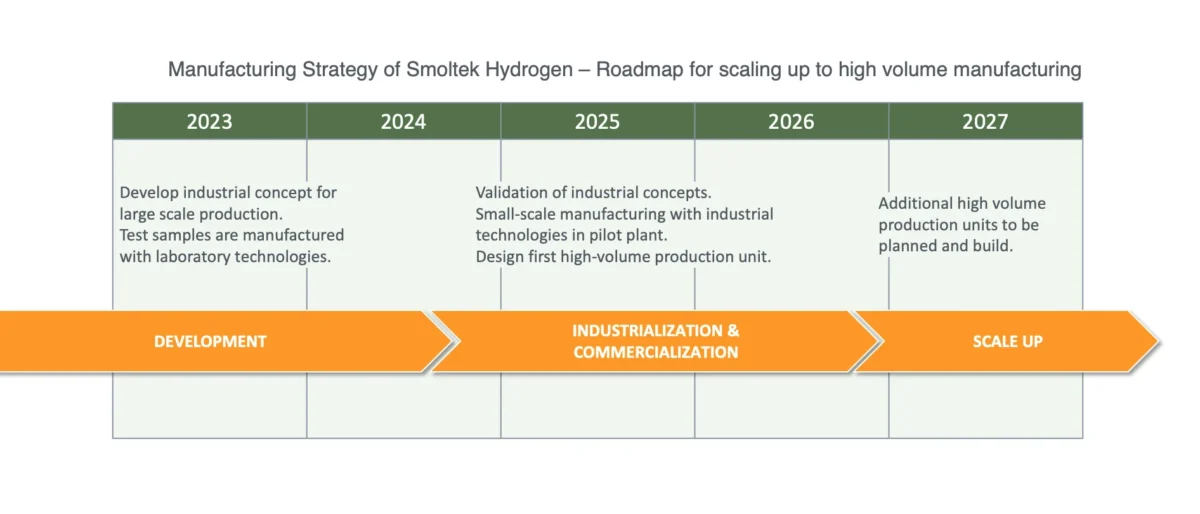

Besides having a game changing technology, Smoltek Hydrogen also need to be able to manufacture the electrolyzer cell material in large volumes. Today the samples are produced with laboratory technologies, in low quantities and with typical area of only a few square centimeters, whereas the industrial manufacturing concept must be scalable to the high volumes foreseen, which is tens of thousands of square meters a year, and beyond.

An important first step towards industrialization and commercialization of the Smoltek Hydrogen electrolyzer cell material is practical validation of the selected concept for the growth of nanofibers, since it is a different type of Plasma Enhanced Chemical Vapor Deposition (PECVD) process than used today. In order to do this Smoltek Hydrogen has, together with AGC Plasma Technology Solutions, designed a new dedicated Prototype Coater tool that will be placed in the Chalmers MC2 facilities in Gothenburg, where Smoltek currently has its nanofiber fabrication operations.

The Prototype Coater is a powerful tool with small footprint and will provide an important platform for continued development of industrial growth recipes. The ambition with the tool is to combine scalable AGC linear hollow cathode PECVD technology and our expertise in growing carbon nanofibers. We fine tune different growth conditions and select the parameters most suitable for further scale-up. The tool will also enable us to manufacture representative samples to customers with industrial scalable technology.

Shafiq Kabir, Head of Volume Processes at Smoltek Hydrogen

Based on the learnings from validation of the Prototype Coater, Smoltek Hydrogen aims to order a Pilot Coater, which is a smaller version of a high-volume tool. This is also a crucial component of AGC’s business model, since they guarantee the performance of the volume machine if their smaller coater is used to specify its requirements. The Pilot Coater will be used to produce test series for customers as well as for verification of the production technologies before volume manufacturing.

About AGC

AGC Plasma Technology Solutions is a new business unit within AGC Glass Europe SA, a European leader in flat glass. AGC Plasma Technology Solutions is providing low-pressure plasma coating technology and equipment. AGC Plasma is an expansive team of plasma coating experts specialized in innovative PVD and PECVD applications from R&D and new product development all the way through to equipment manufacturing and operational management of mass production coating plants. Visit the website www.agc-plasma.com to learn more about the equipment and services offered by AGC Plasma Technology Solutions.

People pictured in the top photo, from left: Amin Saleeem, Bastien Penninckx, Shafik Kabir, Erwan-Axel Morrisson (AGC), Fabian Wenger, Jeroen Schotsaert (AGC), Ellinor Ehrnberg, Réka Simon-Balint.

Your data will be handled in compliance with our privacy policy.