Sign up for our newsletter!

Your data will be handled in compliance with our privacy policy.

Your data will be handled in compliance with our privacy policy.

Smoltek is a Gothenburg-based materials technology company that specializes in research and development of applications based on carbon nanofibers, which can create new products with revolutionary properties.

Smoltek conducts advanced applied industrial research, where researchers use strictly scientific methods and principles. Most of the time, the researchers start from carbon nanofibers to then investigate which other metals, dielectrics etc. can be coated on the nanofibers (in several layers) in order to achieve the desired properties.

Just over a third of all employees at Smoltek are doctors – or PhDs as they usually say. PhD is an academic research title, and our doctors have been awarded in the following areas: Technology and business strategy, Theoretical Solid-State physics, Microelectronics and Nanoscience, Chemistry, Materials Science, and Microtechnology and Nanoscience.

Smoltek are entering new applications, based on carbon nanofibers, that no one has tried before. This means that there are also no established theories or other research results to start from. This also means that Smoltek’s researchers mainly work hypothesis-driven, i.e. they must investigate how different materials, gases, processes, tools, etc., should work or which nanostructures should be produced.

Advanced hypotheses and material selection

It can sometimes take several months of work to arrive at the best way to coat a catalyst material (for example, iridium) on the carbon nanofibers. During the work, the researchers try to determine, among other things, whether the iridium should be crystalline or amorphous. Should the carbon nanofibers be attached and grown on a smooth or rough surface? Should it be metallic or made up of various oxides? Will it be better if you mix in some other transition metal in the substrate? If so, which one? And so on…. In these experiments, countless combinations are tested where results are measured and compared, and the researchers begin to understand causal relationships (what affects what?).

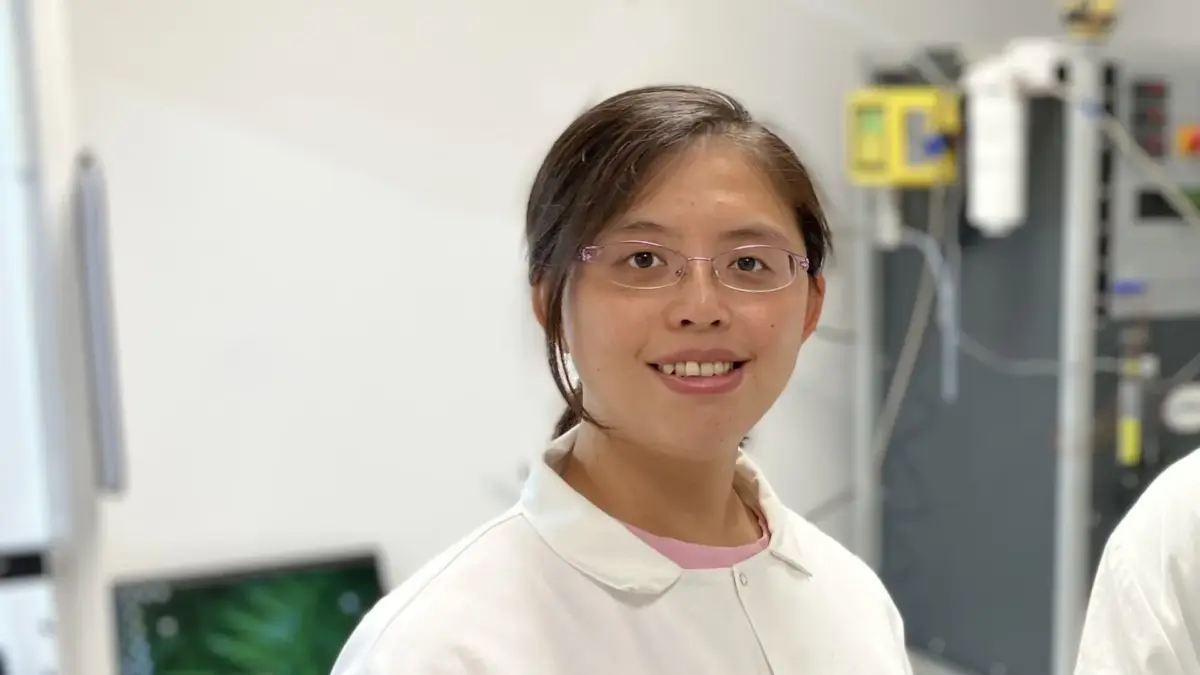

In the example above, with iridium, existing research was studied by Dr. Xin Wen, who before her time at Smoltek did her dissertation on catalytic nanoparticles at Chalmers. Initially, she studied scientific publications to increase knowledge of how iridium could conceivably be deposited on a carbon nanofibers in an electrolyzer anode. Hypotheses were then set up, i.e. Dr Xin Wen made various assumptions about how iridium should work together with carbon nanofibers, and then a series of experiments were performed to see if the hypotheses were correct, as well as to arrive at the best configuration.

This is a highly simplified description, as there are usually many parameters that affect the outcome; for example, how much hydrogen is produced with a certain amount of electric power in an electrolyzer?

Most of the time, this work means that a large number of experiments must be carried out, where, for example, the length, thickness and density of the nanofibers on the substrate (should they be placed sparsely or densely, in which pattern?) etc. are varied. The next step is to control the temperature of the process chamber, gas flow (which gases interact best?) where pressure and geometry are to be varied. But before placing the material sample (prototype) in the process chamber, you also need to test different pretreatment methods, and which metals are most suitable to start growing fibers on.

This work is carried out by Smoltek’s researchers at Chalmers’ cleanroom laboratory for nanotechnology, called MC2. It takes place partly in Smoltek’s proprietary PECVD tool, partly in Chalmers tools. PECVD stands for Plasma Enhanced Chemical Vapor Deposition and involves controlling gases in a chamber with the help of a plasma and electric fields, so that the gas molecules react in a specific way, which starts a process so that the nanofibers (placed on catalysts, in predetermined patterns) start to “grow” in the direction of the electric field from the substrate.

At Chalmers, but also at other universities and research institutes, scanning electron microscopes and other advanced equipment are then used to investigate the morphology of fiber growth and later how the nanoparticles of iridium have attached to the fibers, or to measure efficiency, losses, etc. Based on this, the researchers try to understand how they can improve on the next material.

In this way, Smoltek researchers manufacture extremely small structures, where the basis is carbon nanofiber surfaces, which is then functioning as an electrode, or a sensor, or an electrocatalyst by using different nanotechnologies to deposit various layers on top of the carbon nanofiber.

In order to do this, relevant postgraduate training is required, as well as an established network within the current research in the field. Many of Smoltek’s collaborations are carried out with the researchers’ former colleagues, who are usually professors, or other collaborations with research groups at various universities.

Research conferences, peer review and publications

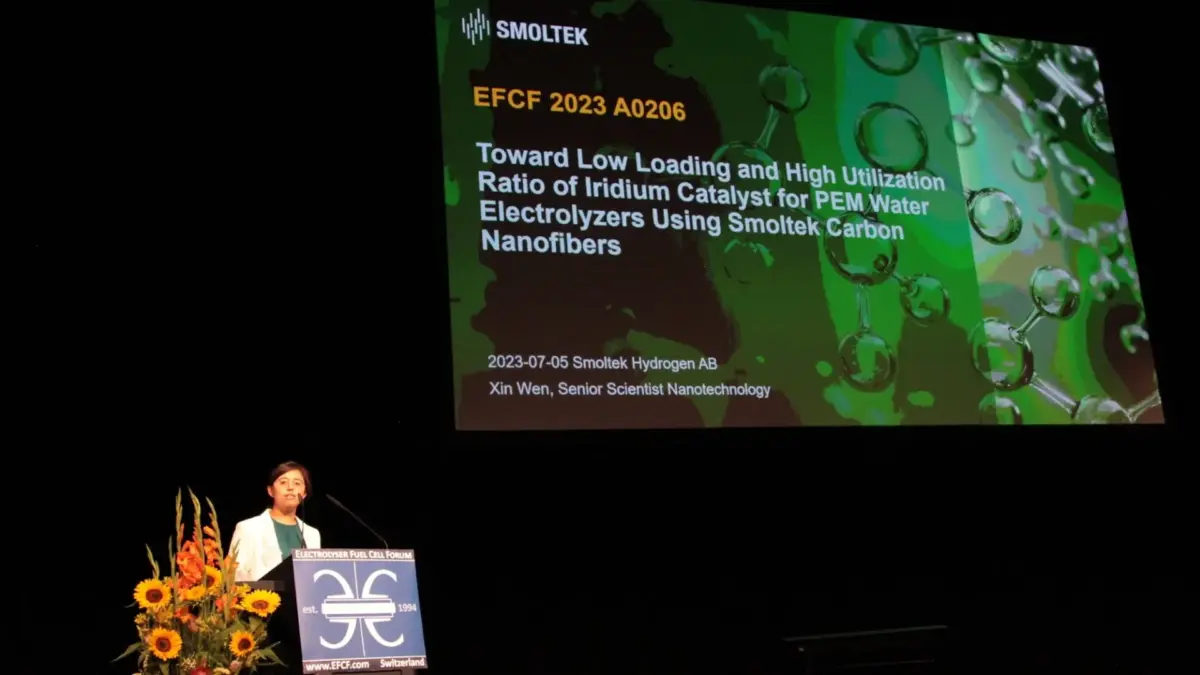

Smoltek’s researchers actively participate at various scientific conferences, where a mix of academic and privately funded research is presented and discussed. To be able to present their latest results at these conferences, the contribution must first be approved by different committees, consisting of prominent researchers in the respective fields. These assess whether the experiments can be repeated, they study the publication’s references to, among other things, understand that the results constitute new and relevant knowledge, and they review that the study is of sufficiently high quality for reliable conclusions to be drawn.

Smoltek’s researchers write scientific publications partly to get a stamp of approval that the research is of the right quality, partly to show merit when Smoltek applies for research grants. This is also what Smoltek emphasizes to make it clear that the company conducts highly qualified research, which by definition means that Smoltek creates new knowledge.

Smoltek’s research is reviewed and published in scientific journals after a so-called peer review process, which confirms its academic quality. For instance, this example.

This is a standard in the research world and confirms that what Smoltek presents is new knowledge. In order to have the research published, it must be unique and contribute to the research front. The same criteria apply to the company’s patent applications – Smoltek can only obtain a patent if the application develops new innovations and has a qualified inventive step.

Smoltek regularly participates in scientific conferences, such as the Electrochemical Society (ECS), where the company’s research results are presented to a scientific audience. These conferences also place high demands on the quality of the research.

In summary, Smoltek conducts qualified research, which is shown through the company’s research grants, collaborations with universities and industry, as well as participation in scientific conferences and publications in scientific journals.

Join us and become a superstar in nanotechnology!

Would you like to work with advanced research at Smoltek?

Do you like:

Welcome to send in a spontaneous application.

Your data will be handled in compliance with our privacy policy.