Sign up for our newsletter!

Your data will be handled in compliance with our privacy policy.

Your data will be handled in compliance with our privacy policy.

For industrial enterprises, bringing new technologies into existing product lines follows a structured process. Understanding this process is vital for high-tech companies seeking integration partnerships. Here, we explain the systematic journey that governs how industrial enterprises evaluate and adopt innovations, and how high-tech companies can create revenue opportunities at each stage along the way.

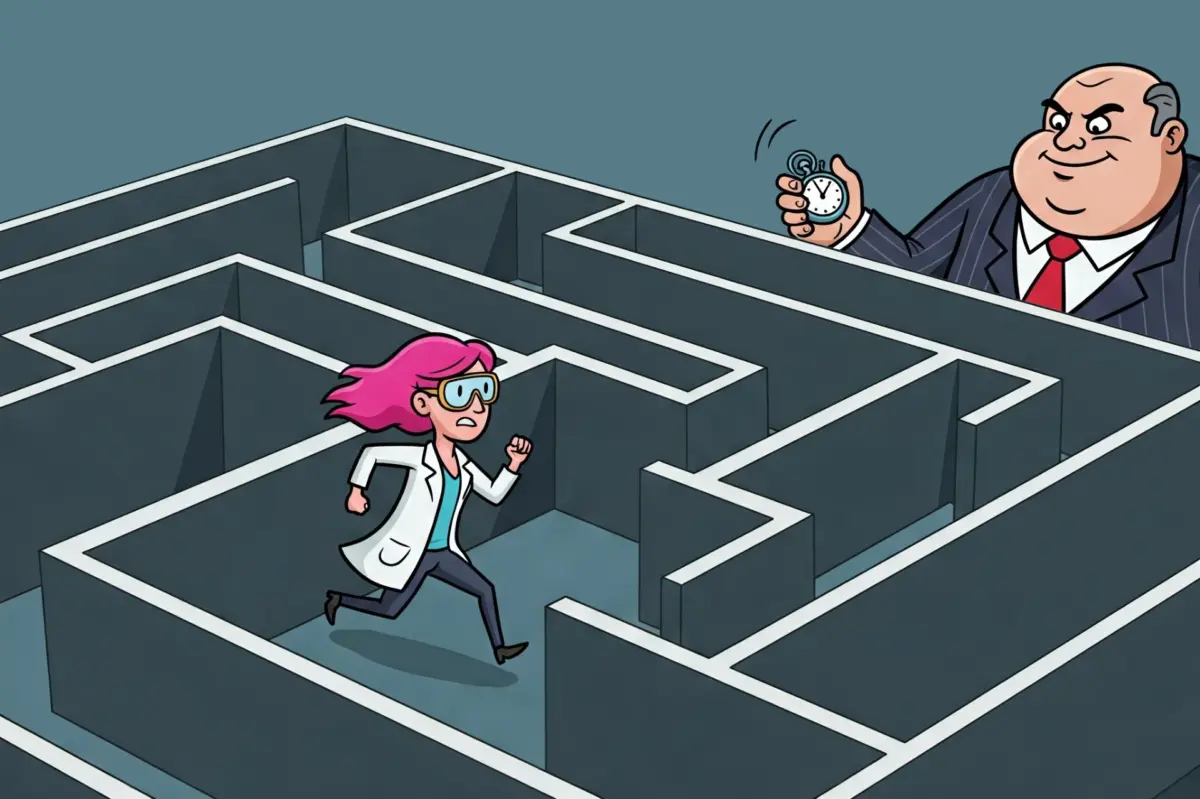

Industrial enterprises follow a methodical approach when integrating external innovations into their product lines. For high-tech company shareholders, this process can seem unreasonably long and full of arbitrary obstacles. However, understanding that it’s actually a fairly orderly six-stage process can help innovative companies navigate these waters more effectively and identify revenue opportunities at each stage. In this article, we take a closer look at how industrial enterprises operate and what this means for high-tech partners.

The first stage begins either with the industrial enterprise identifying a specific problem and actively seeking a solution, or with the high-tech company pitching an innovation that could open up new business opportunities.

For the high-tech company, this early stage is all about building trust and demonstrating technical potential. They need to clearly and concisely describe what their technology can do and why it is worth pursuing by the industrial enterprise.

Often, industrial enterprises test smaller lab samples to get a first indication of the technology’s potential. This may be to understand how the technology works and performs.

It is common for industrial enterprises to have several parallel evaluations running simultaneously. Many technologies are dropped at this stage because they do not show enough potential or because they do not fit with the enterprise’s long-term strategy and goals. Therefore, the high-tech company must make a strong first impression and present its technology in a way that captures the interest of the industrial enterprise and demonstrates tangible value.

This stage is often called the fuzzy front end because many ideas are evaluated simultaneously, and the process is relatively informal. While this stage can traditionally take considerable time, the timing may accelerate dramatically if the technology addresses an urgent market need or offers exceptional value.

Once the high-tech company has made a strong impression and demonstrated promising initial results, the industrial enterprise typically moves forward by establishing a formal collaboration. This might take the form of a feasibility study, a consulting agreement, or a joint development project. This formal engagement involves in-depth analysis of both technical and commercial aspects led by the industrial enterprise.

Importantly, this stage often marks the beginning of both the commercial relationship and the co-creation process, with the industrial enterprise becoming a paying customer through these various forms of collaboration. This co-creation – where both parties work together to develop and refine the technology – begins modestly but lays the foundation for deeper integration. Though typically modest in scale, these early revenues can provide vital support for the high-tech company while building toward larger opportunities.

On the technical side, the industrial enterprise defines detailed performance, reliability, and compatibility requirements. They investigate whether existing production lines can be used or new investments are required. Risk assessments are performed for potential technical challenges, including whether the new technology is fully developed, scalable, or compatible with existing systems.

At the same time, the business potential is carefully analyzed. The industrial enterprise looks at expected sales volume, return on investment, total cost of ownership, and time to market. It conducts a detailed market and competition analysis and identifies potential customers.

This co-creation study stage in traditional corporate environments might take 12–24 months, though it may proceed much faster if the industrial enterprise sees a compelling market opportunity or competitive advantage. Equally, the process might temporarily slow or pause if market conditions change or other priorities emerge, before resuming when timing is more favorable.

Once the industrial enterprise has chosen its technology supplier, the collaboration deepens through a supplier development agreement. This gives the high-tech company expanded business opportunities and access to the industrial enterprise’s resources and knowledge. At the same time, the industrial enterprise secures access to the new technology with a partner who can deliver the required quality and volume.

This agreement typically defines common goals for technology development, with specific performance, reliability, and cost requirements. It includes milestones for quality control and plans for integrating the technology into the industrial enterprise’s production.

The supplier development agreement usually includes provisions for compensation during this deepened co-creation stage, such as consulting fees, milestone payments, or cost-sharing arrangements. These agreements provide the high-tech company with important revenue streams while working towards full commercialization.

For high-tech companies, this stage represents a significant strengthening of the customer relationship, with more substantial and predictable revenue opportunities.

With the supplier development agreement in place, the industrial enterprise begins detailed design work, which typically takes 6–12 months in conventional settings, though with innovative technologies and motivated partners, this timeline can be substantially shortened. During this stage, extensive technical documentation is produced, from drawings to material specifications.

The high-tech company now assumes an important role as a paid technical advisor in this co-creation process. This consulting revenue often becomes more substantial, helping sustain operations while working towards full-scale production.

As the industrial enterprise progresses with design work, the technology is fine-tuned to specific products and applications. Materials and processes are reviewed to ensure supply chains are ready for future volumes.

Contracts are updated to clarify responsibilities, intellectual property rights, cost structures, and timelines. Successful projects feature close interdepartmental collaboration at the industrial enterprise, involving marketing, manufacturing, purchasing, and R&D to ensure the design is feasible, meets all requirements, and can be manufactured cost-effectively.

When the industrial enterprise approves the design, the most resource-intensive phase begins. This stage for established industries with conventional technologies can take 12–36 months, though market urgency and technological readiness can compress this timeline considerably. The industrial enterprise produces prototypes that undergo rigorous testing to ensure functionality, reliability, and compliance. Several types of prototypes are used:

Testing progresses from the component level to complete system prototypes, often requiring multiple design iterations to resolve issues and optimize the system.

The high-tech company’s role during this phase is crucial, as they must demonstrate that their technology works as intended under all conditions. This often involves accelerated life testing, environmental testing, and compliance testing to ISO standards.

In parallel, the industrial enterprise develops and validates the manufacturing process. Suppliers begin delivering pre-production parts in increasing quantities, and pilot runs train operators and stabilize the process for full-scale production.

For the high-tech company, this phase typically involves increasingly substantial commercial agreements, as the relationship moves from development toward production. These agreements can provide significant revenue even before full commercial launch.

After successful testing, the project enters the deployment phase. The industrial enterprise shifts responsibility from the development team to the regular line organization for ongoing production, distribution, and support. Production often starts cautiously and gradually increases as processes stabilize.

For the high-tech company, this phase means the beginning of long-term supply contracts and stable, substantial revenue streams. A successful launch with one industrial enterprise can open many doors, making it easier to attract new customers and expand into new market segments. This is when the high-tech company begins to reap the full rewards of its innovation and persistence.

The relationship often continues evolving, with the industrial enterprise incorporating the technology into additional products or applications, creating further growth opportunities for both parties.

The process from first contact to finished product in conventional industrial settings can take several years, especially in industries with high safety and reliability requirements. However, with the right technology and partner alignment, these timelines can be significantly accelerated. It’s important to understand that high-tech companies are typically engaged in multiple such processes simultaneously with different industrial enterprises, each at its own stage of development.

These parallel relationships exist at various stages of maturity, creating a portfolio of opportunities that develop at different paces. Success with one industrial enterprise often creates positive momentum, accelerating discussions with others as the technology proves its value in real-world applications.

This portfolio approach creates corresponding revenue potential increasing at each stage. While early-stage engagements might involve modest consulting fees, later stages can deliver substantial production contracts.

It’s crucial for high-tech companies to have sufficient financial resources to bridge the development period and the ability to adapt to each industrial enterprise’s processes. Building trust by delivering on promises is essential.

Technical excellence is necessary but not sufficient. Innovative technology companies must also demonstrate they are reliable partners who can handle the demands of each development phase and communicate effectively with industrial enterprises. The key is being strategic, patient, and persistent while recognizing that timing can vary significantly based on market conditions and enterprise priorities.

In our next article, Ellinor Ehrnberg shares how Smoltek Hydrogen is adapting its development schedule to keep pace with where the key potential buyers of Smoltek Hydrogen’s technology are in their product development. Then we’ll explore how truly disruptive technologies can dramatically accelerate these traditional timelines, creating opportunities for forward-thinking companies to gain a decisive market advantage.

Your data will be handled in compliance with our privacy policy.