Sign up for our newsletter!

Your data will be handled in compliance with our privacy policy.

Your data will be handled in compliance with our privacy policy.

Did you miss the webinar with Smoltek’s CEO, Håkan Persson, where he talked about Smoltek’s future direction? No worries! We have your back covered. This summarizes the highlights of Håkan’s presentation.

On June 4, Smoltek held a webinar on the company’s future. The speaker was Håkan Persson, CEO of Smoltek, and the moderator was Albin Kjellberg, known in Sweden for his talks, podcasts, and tips on stock, savings, and funds. This blog post summarizes Håkan Persson’s speech. In a follow-up blog post, we will report on all the questions raised after the presentation and Håkan Persson’s answers.

Smoltek is a company with revolutionary technology and enormous potential. According to Håkan Persson, Smoltek has the most significant potential of all the companies he has worked with. The company’s technology is very relevant in today’s technology development, which requires higher performance and smaller, cheaper, and more efficient components. Smoltek’s technology can meet these demands through innovative and disruptive solutions.

Founded in 2005, Smoltek works with nanotechnology based on 20 years of research at Chalmers University of Technology in Gothenburg. The company was listed on Spotlight in 2018. Smoltek aims to solve advanced material engineering problems with its proprietary technology, SmolGROW. This technology creates a three-dimensional surface structure by controlling the growth of carbon nanofibers. This provides a larger active surface for electrical and chemical processes, which can be used in various application areas.

Smoltek’s business model is based on an incubator model where business opportunities based on the core technology SmolGROW are identified and developed with partners into market-ready companies. Smoltek makes money by licensing the technology and selling the subsidiaries.

Smoltek has recently announced that it is exploring the possibility of selling all or part of its subsidiaries Smoltek Semi and Smoltek Hydrogen, or their technology, to highlight the value of the company and ensure continued growth. There is a large gap between the confidence of the stock market and the value that the board and management see in the company. They have begun to reach out to potential stakeholders to maximize shareholder value.

To ensure a structured process and to continue the development, Smoltek is conducting a rights issue. The subscription price is set at SEK 0.45 per share, which can provide the company with SEK 26 million before expenses. The issue is subject to a minimum subscription of 80 percent. Approximately 50 percent of the issue is initially underwritten by subscriptions and guarantees from investors who have followed the company over time.

Smoltek is an innovative deep-tech company with great potential in two business areas: semiconductors and hydrogen. The company has an experienced management team and board of directors and targets volume production between 2025 and 2027. The technology platform has the potential to expand into many other application areas. Smoltek has created much value in recent years that it can capitalize on.

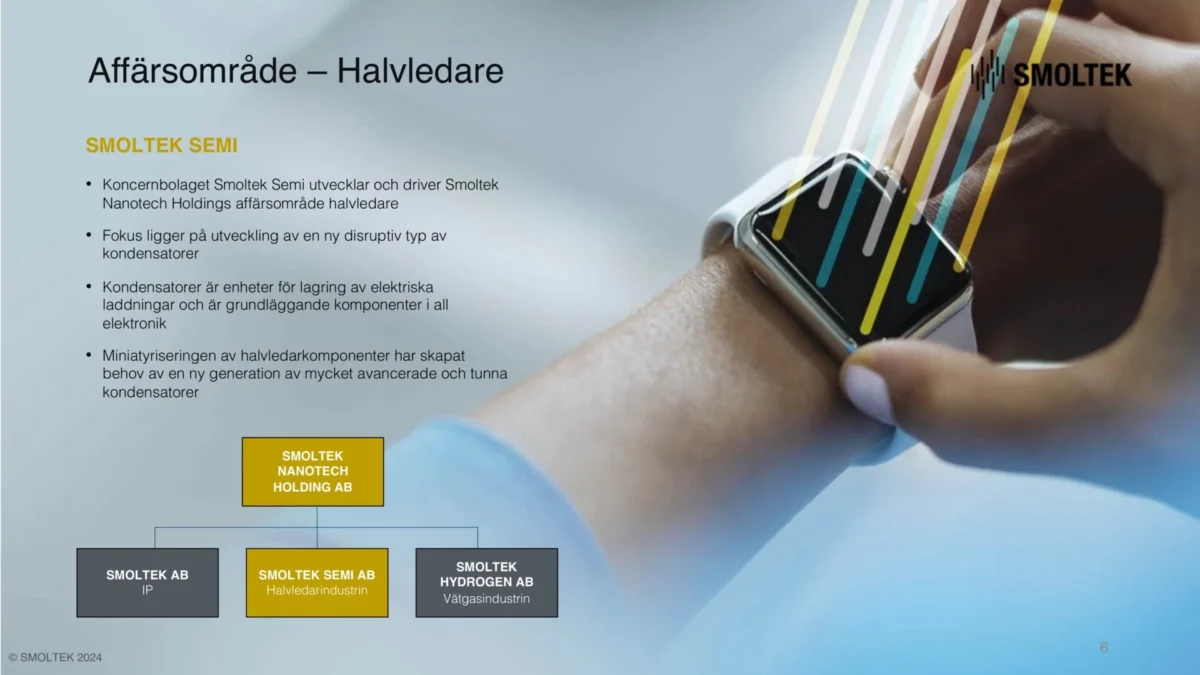

Smoltek focuses on semiconductors and hydrogen. In semiconductors, it develops ultra-thin capacitors for application processes in mobile phones and other advanced electronic components. In hydrogen, the company is developing high-performance cell materials for cheaper and more efficient production of fossil-free hydrogen.

After this introduction, Håkan Persson goes into each business area to explain its potential. He started with Smoltek Semi – the subsidiary that serves the semiconductor industry.

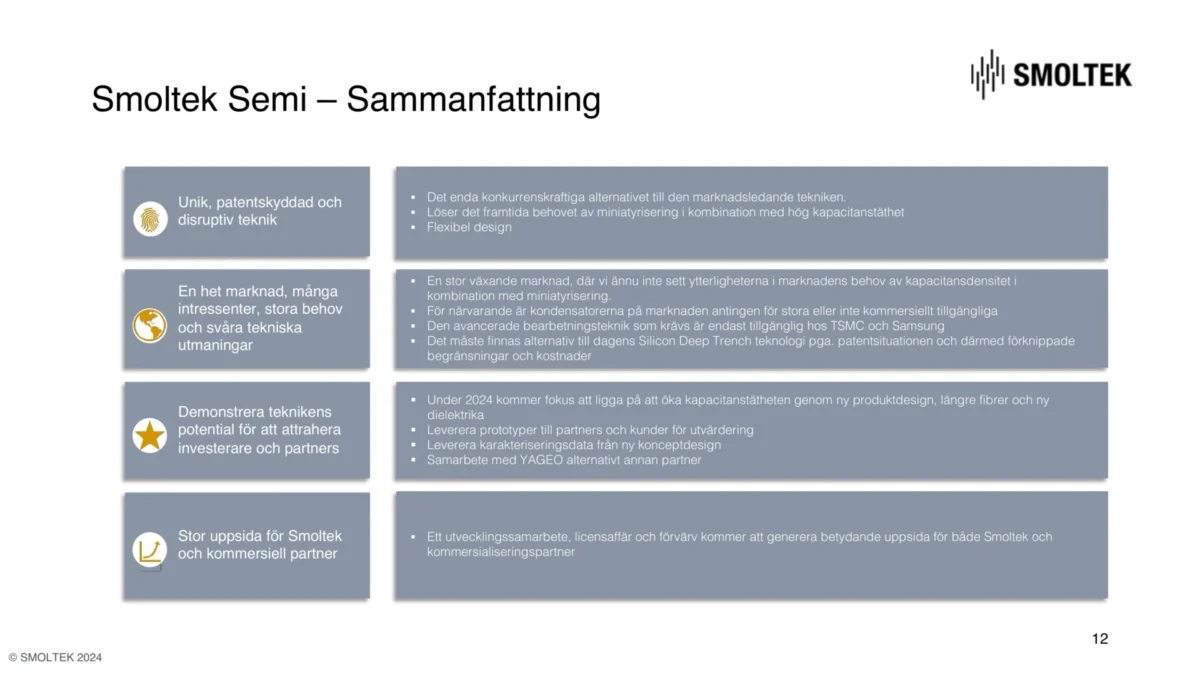

The continuous development of more and more transistors on chips requires new, thin, and advanced capacitors. Smoltek’s technology meets these needs by creating high capacitance density while maintaining performance, solving miniaturization problems, and improving the functionality of modern semiconductors.

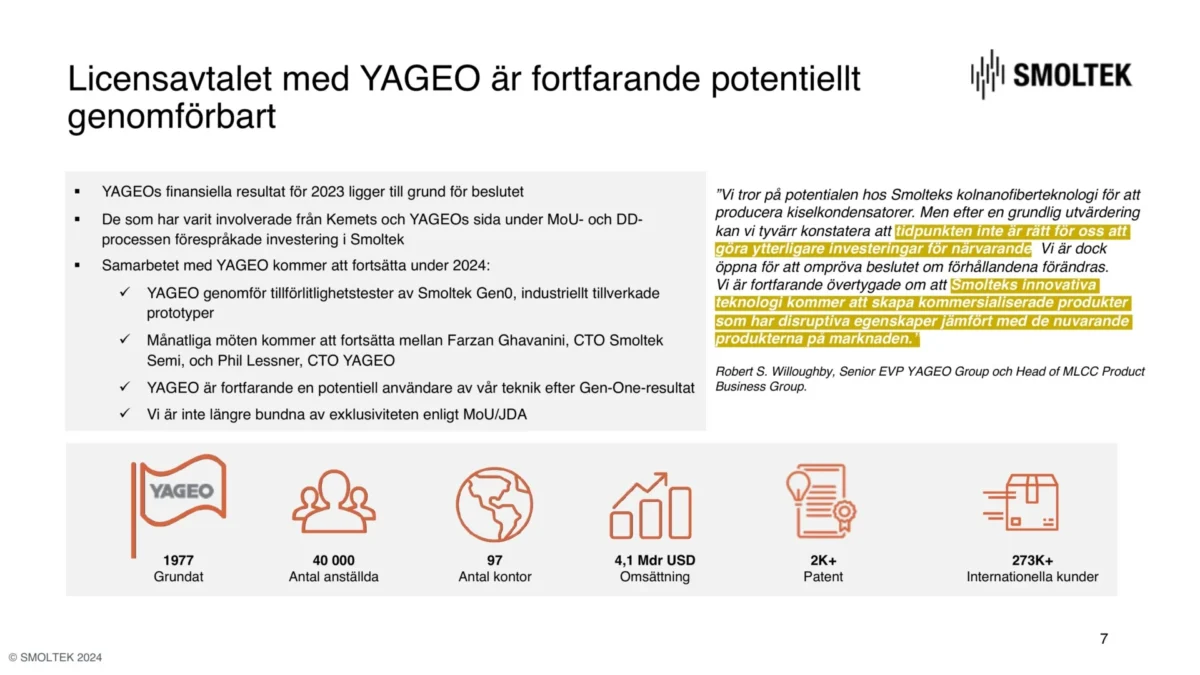

Before continuing, Håkan Persson addressed the elephant in the room. Negotiations with YAGEO were suspended due to their internal circumstances and priorities, not distrust of Smoltek’s technology. YAGEO still sees the potential of technology and may return to collaboration if its conditions change.

Robert S. Willoughby, director of YAGEO’s Multilayer Ceramic Capacitor Division, explains:” We believe in the potential of Smoltek’s Carbon Nanofiber technology to produce Silicon capacitors. However, after a thorough evaluation, we regret to conclude that the timing is not right for us to make further investments currently. Nevertheless, we remain open to revisiting the decision if conditions change. We are still confident that Smoltek’s innovative technology will provide commercialized products that deliver disruptive capabilities compared to the current products on the market.”

The decision to break off negotiations was based on internal priorities. YAGEO still wants to become a technology provider and is interested in Smoltek’s technology. Smoltek will now approach more players in the market as exclusivity agreements with YAGEO no longer bind it.

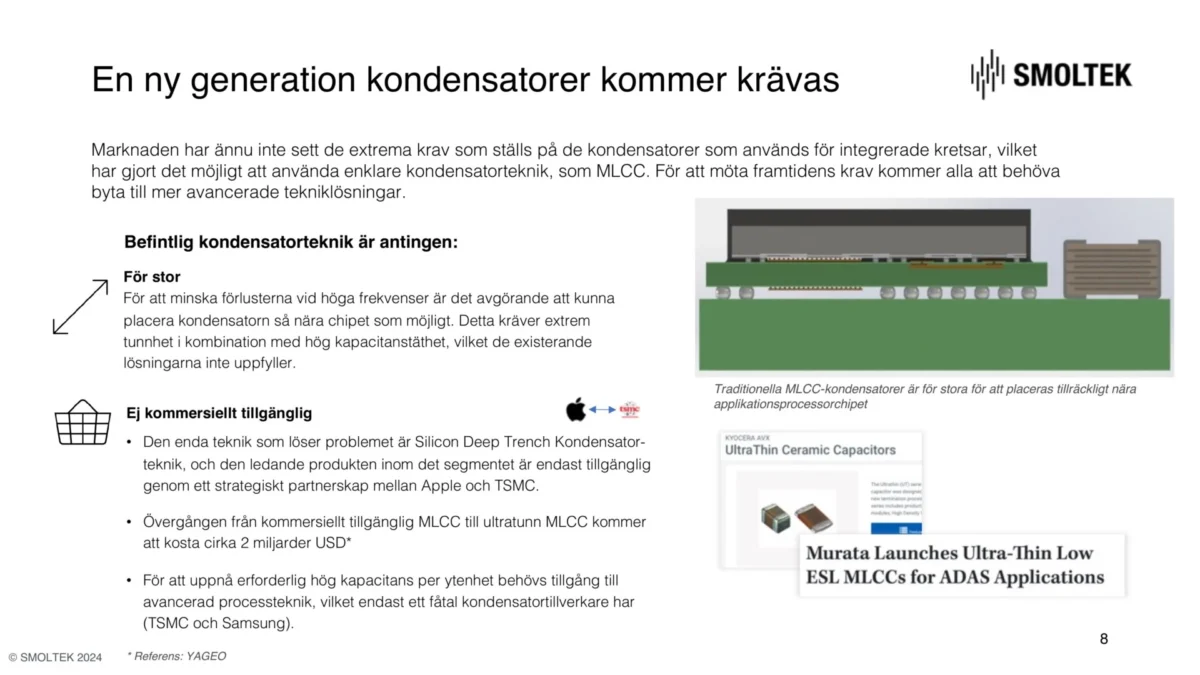

The market requires a new generation of capacitors with high capacitance density, and Smoltek’s technology can meet these requirements. Multilayer Ceramic Capacitors (MLCC) cannot meet the new requirements, which gives Smoltek’s CNF-MIM capacitors a unique position.

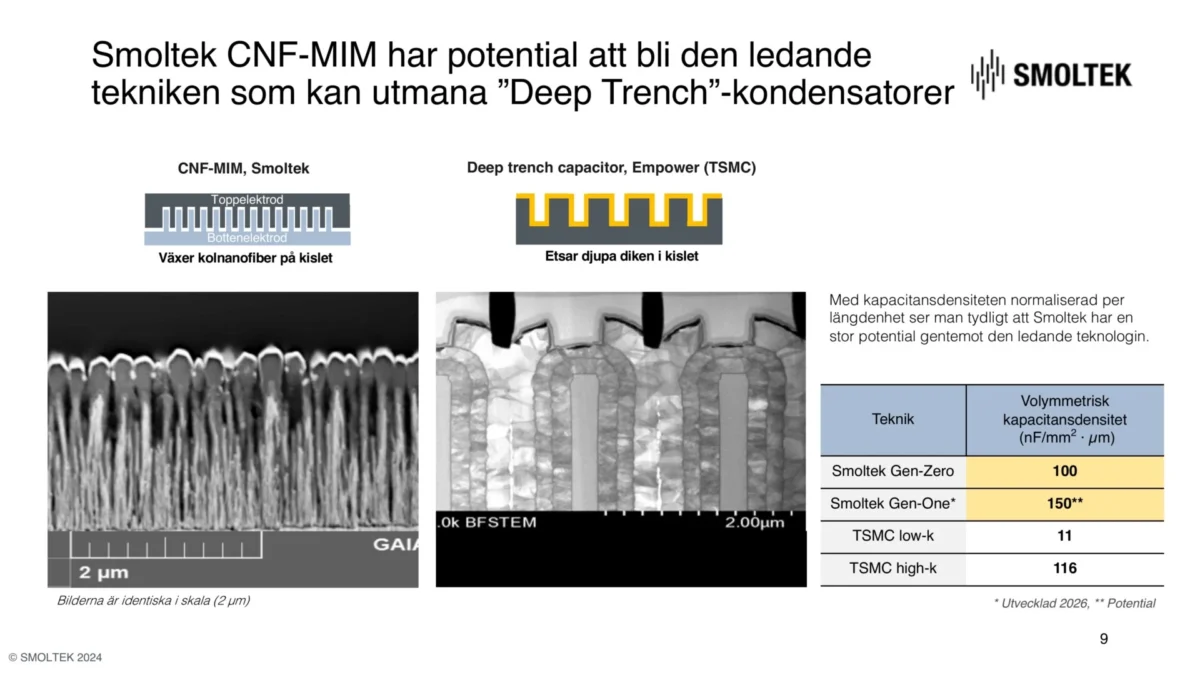

The existing option to meet these needs is silicon deep trench. It is developed in collaboration between Apple and TSMC, creating intellectual property and competitive challenges for other players in the market. Smoltek offers a more competitive solution by adding material to the substrate, which provides high capacitance and is robust, rather than etching material away from the substrate, which limits capacitance and is fragile. Smoltek achieves per-micrometer capacitance levels on par with the best currently available. With our next generation, Gen 1, Smoltek’s CNF MIM capacitors will have a significant increase in capacitance.

Smoltek’s CNF-MIM capacitors enable higher performance and are a cost-effective alternative to silicon deep trench. The technology is compatible with standard CMOS manufacturing processes and can be used by existing contract manufacturers.

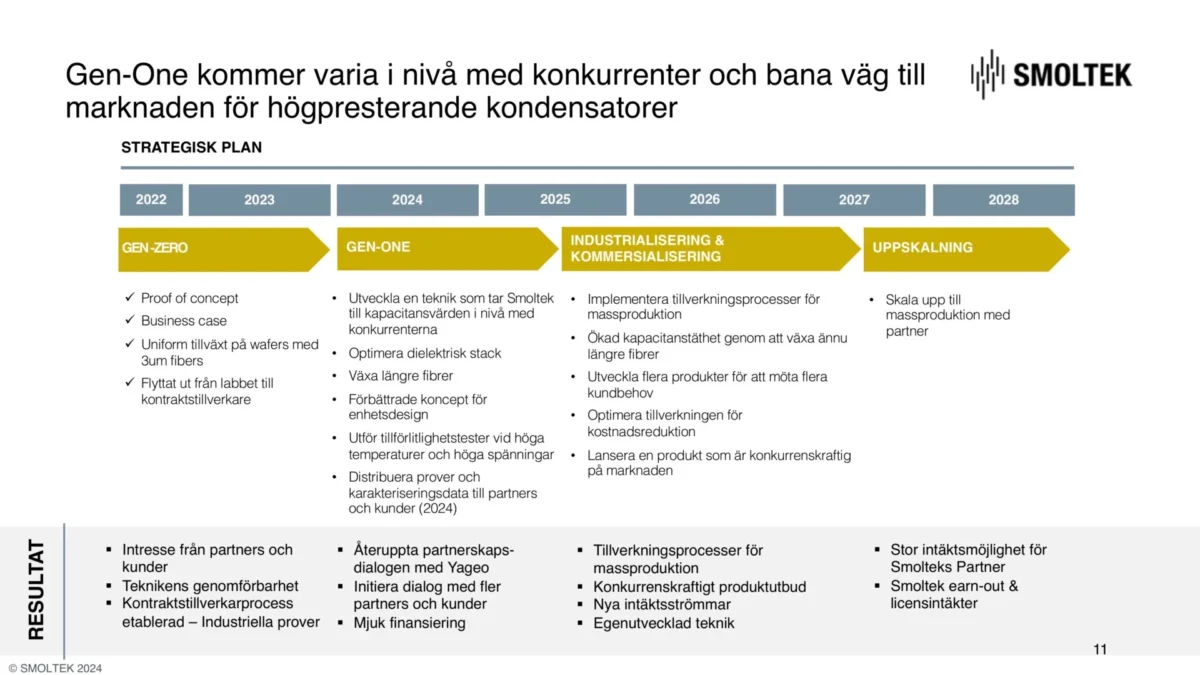

Smoltek sees an opportunity to create an auction situation around its technology by re-engaging with YAGEO and other potential partners. The company is also working on soft funding through participation in EU-related projects.

Smoltek Semi offers a competitive alternative to market-leading technologies for future miniaturization and high capacitance density needs. In 2024, the focus will be on increasing capacitance density and delivering prototypes to partners for evaluation. There are significant commercial opportunities for Smoltek and a potential partner.

Håkan Persson switches gears and talks about Smoltek Hydrogen – the subsidiary that serves the hydrogen industry.

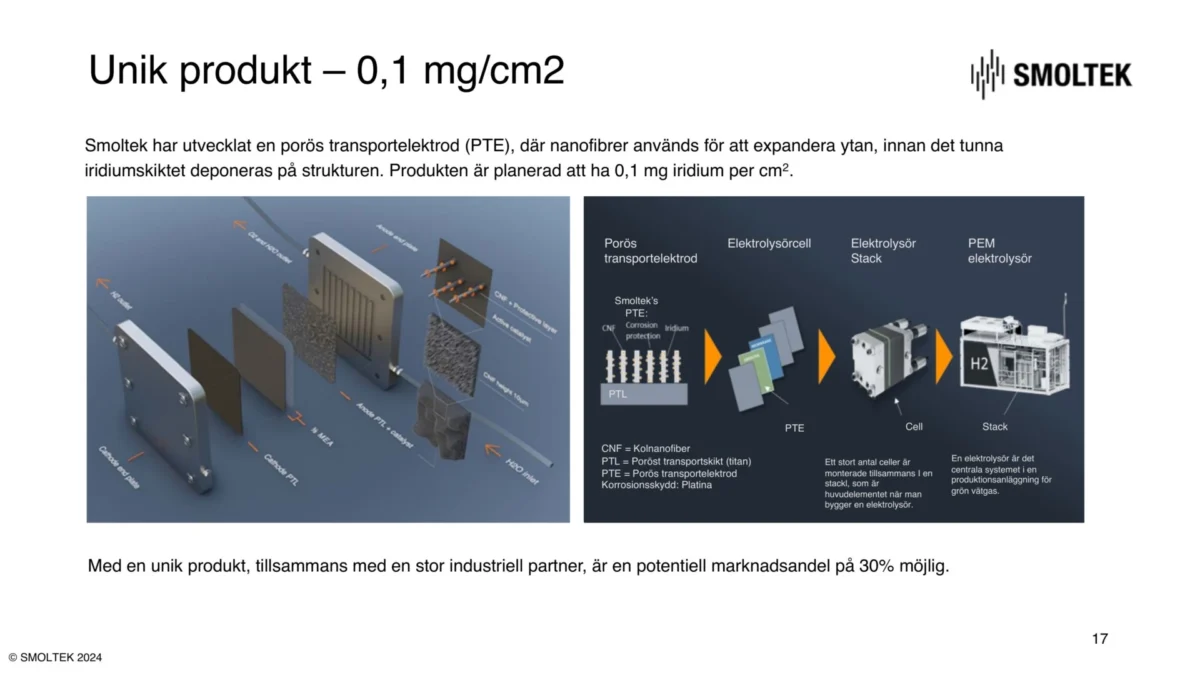

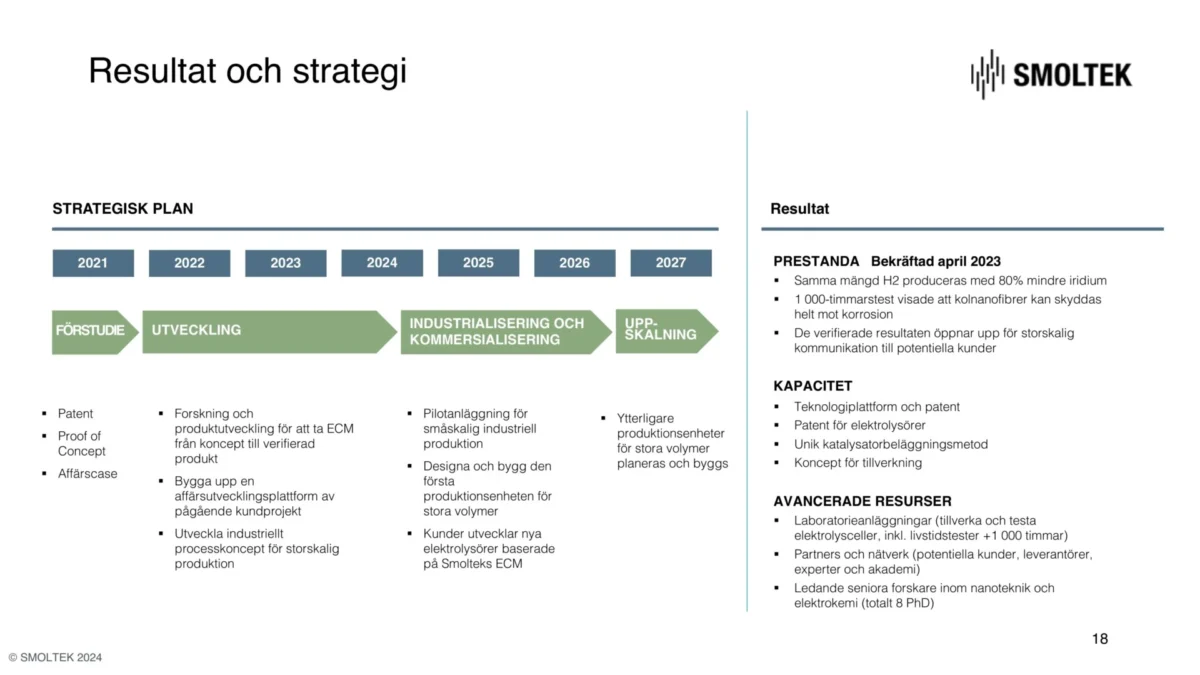

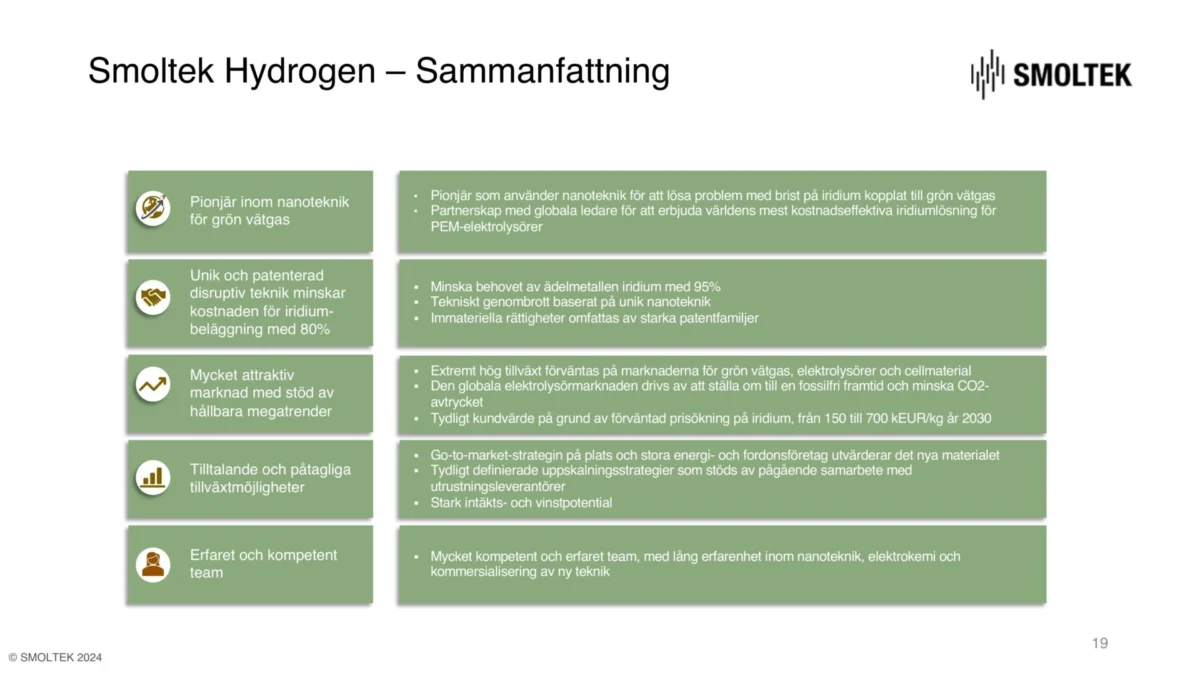

Smoltek Hydrogen is developing a new type of cell material for electrolyzers that can scale up the production of fossil-free hydrogen. This is necessary to combat climate change.

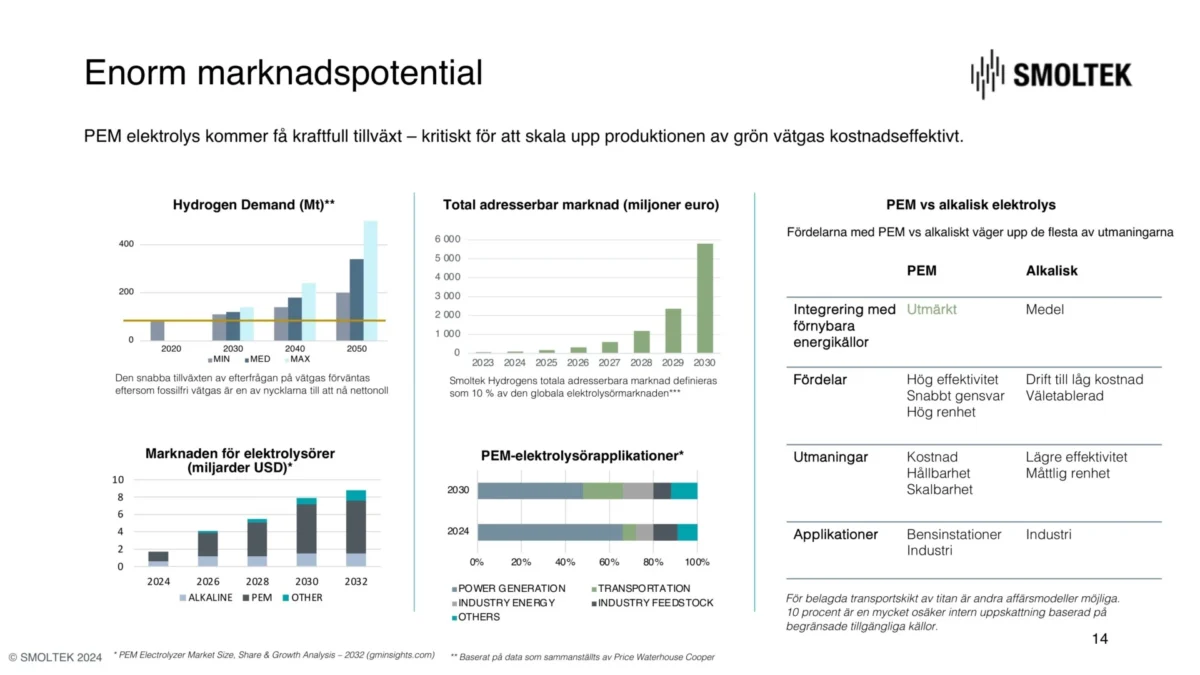

PEM electrolyzers are essential for harnessing energy from intermittent green sources such as solar and wind. They match capacity to energy availability, lowering the cost of producing green hydrogen. Forecasts show a sharp hockey stick increase as the need for this technology is urgent and widespread.

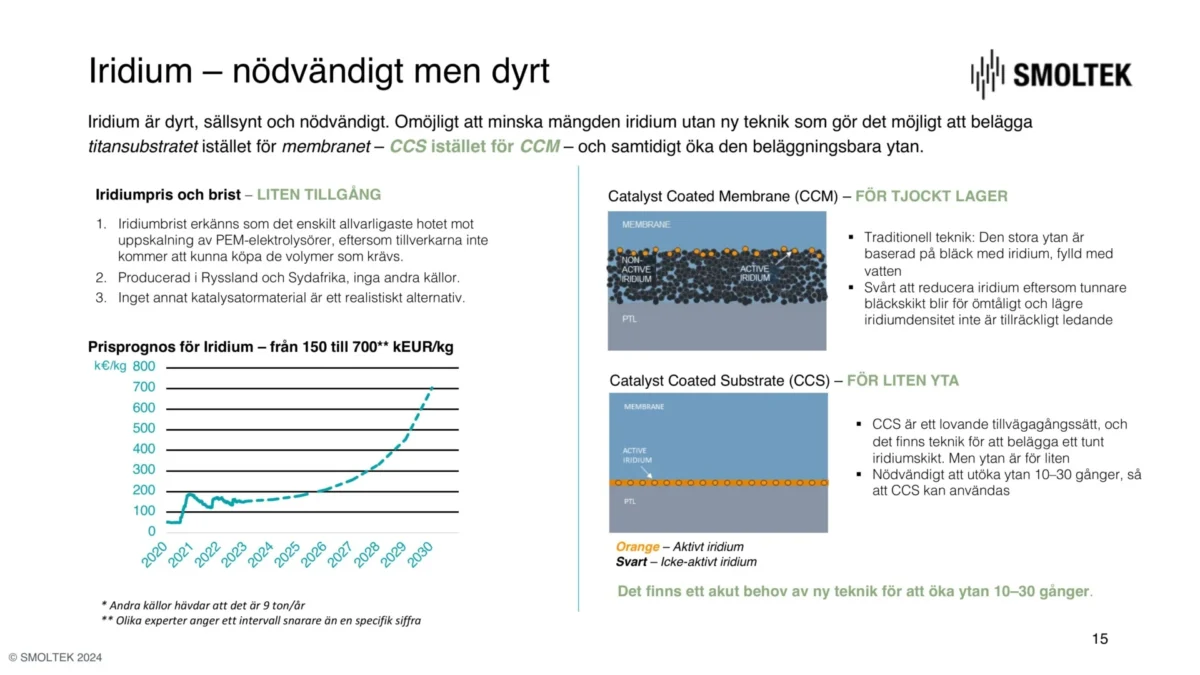

PEM electrolyzers require iridium, an extremely rare and expensive precious metal. Today, iridium costs about € 150,000 per kilogram, but it is expected to reach € 700,000 per kilogram by 2030. Current technology, which mixes iridium into ink on the membrane, is inefficient. The solution is to place iridium on a substrate in contact with the membrane, which requires 10–30 times more surface area.

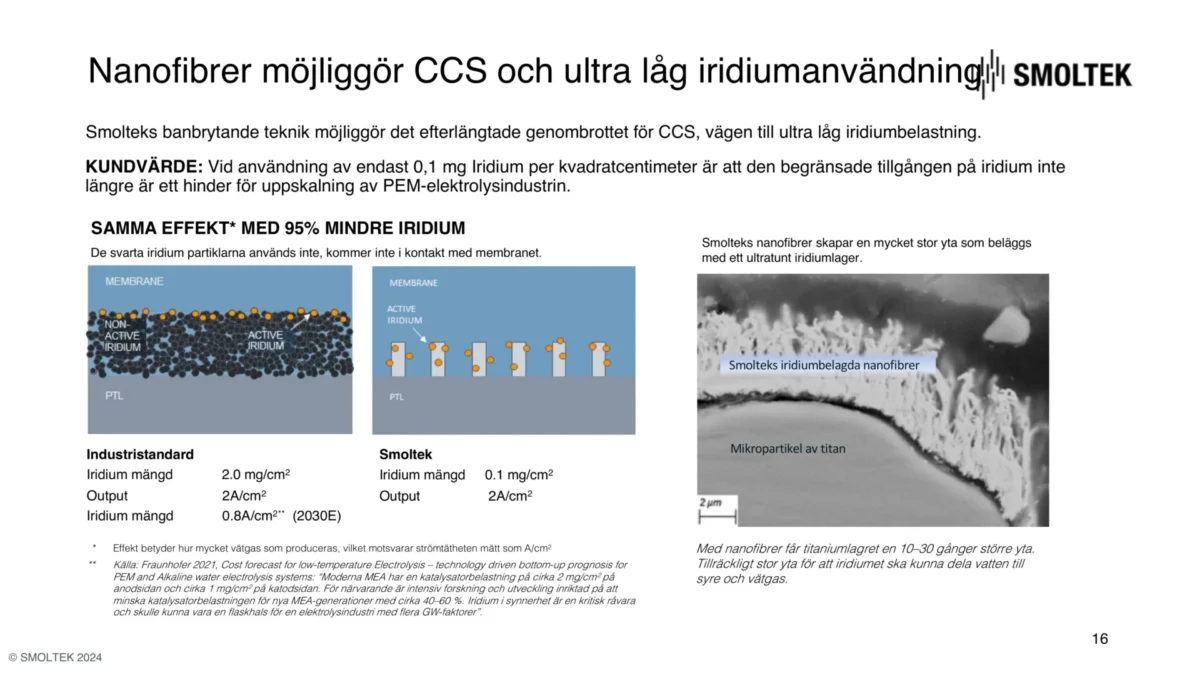

Smoltek’s solution multiplies the surface area in contact with the membrane, producing the same amount of hydrogen with significantly less iridium. This reduces the need for iridium and lowers production costs. A successful thousand-hour test shows a 90 percent reduction in demand. In the lab, we have achieved a 95 percent reduction.

It is reasonable to expect that Smoltek’s cell material will reach a market share of 30% by 2030, which means producing 200,000 square meters of cell material. This would save SEK 10 billion in electrolyzer production costs, creating a strong business case for an industrial partner.

Smoltek has proven its technology and know how to produce the material in large quantities. The next step is to find a partner to industrialize the solution and bring it to market.

Smoltek Hydrogen offers a cost-effective solution to reduce the need for iridium in the production of green hydrogen. The company has solid patents and partnerships with global leaders. The market is growing rapidly, and Smoltek is well-positioned to capitalize on this growth.

Smoltek has created much value not reflected in today’s market capitalization. The company has both the technology and the competence to realize its potential. It is an exciting investment opportunity for both the short and long term.

This was the summary of Håkan Persson’s speech. You can watch the entire speech on YouTube. And don’t miss the next blog post, which details the questions from the audience and Håkan Persson’s answers.

Your data will be handled in compliance with our privacy policy.