Sign up for our newsletter!

Your data will be handled in compliance with our privacy policy.

Your data will be handled in compliance with our privacy policy.

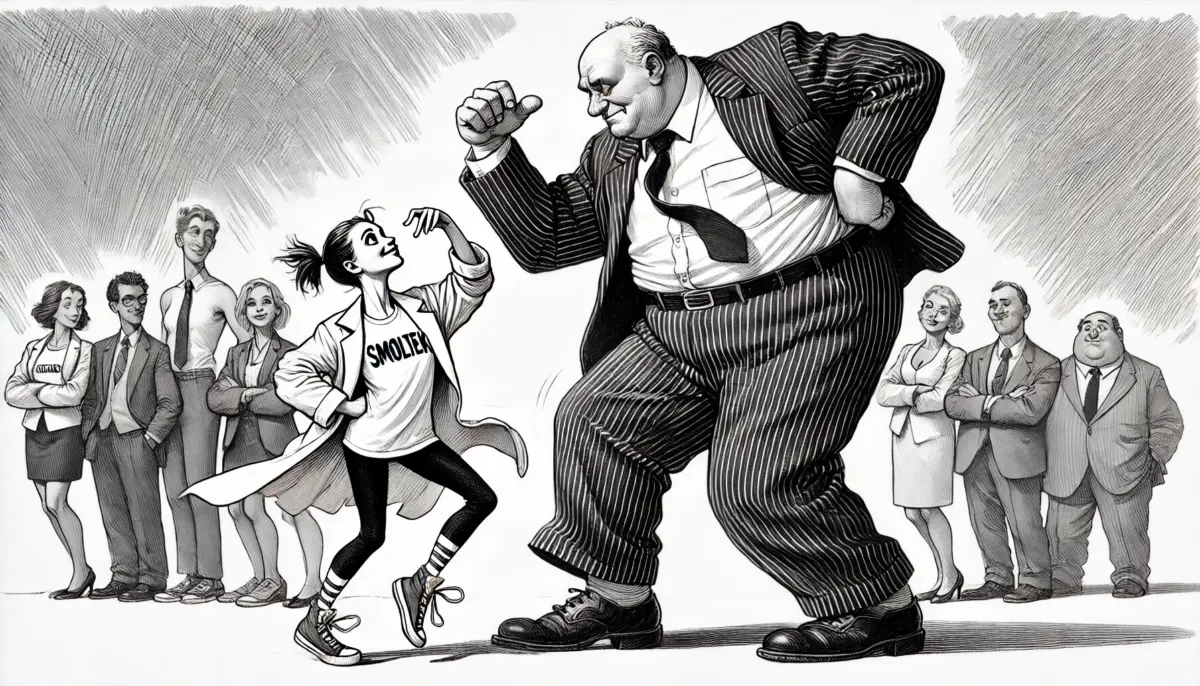

Taking a breakthrough technology from the lab bench to the world market often requires collaboration with large industrial enterprises. In this interview, Ellinor Ehrnberg, president of Smoltek Hydrogen, explains how the company aligns its own development with that of potential buyers while navigating the complex journey from initial interest to strategic partnership.

When an industrial enterprise wants to adopt the technology of a high-tech company, it follows a structured process from initial evaluation to full market integration. As outlined in our previous article Navigating corporate product development as small high-tech company, these processes have six major stages:

Now it’s time to take a closer look at how Smoltek Hydrogen has positioned itself within this framework.

”Our strategy is not to get ahead of our potential customers, but to keep pace with where they are in their process. Some are moving cautiously, others are moving quickly,” says Ellinor Ehrnberg, President of Smoltek Hydrogen. ”Heraeus, with whom we’ve already had a strategic collaboration, I think is already at stage 3 and moving quickly to stage 4. Several others are on the cusp of moving from stage 1 to stage 2 and are ready to take that critical next stage with us.”

Smoltek Hydrogen has developed a unique technology, Porous Transport Electrode (PTE), which drastically reduces the need for iridium in PEM electrolyzers. As we have previously written about in Unlocking the green hydrogen economy and The last crusade for 0.1 mg iridium, green hydrogen is a scarce necessity, which is why PEM electrolyzer manufacturers are desperately looking for solutions to reduce the need for iridium.

”Anyone who makes PEM electrolyzers knows that they need to reduce the amount of iridium used per square centimeter. Today it’s about 2 mg, and we need to get down to 0.1 mg. It’s not just a technical thing, it’s critical for green hydrogen to be economically viable,” says Ellinor Ehrnberg.

This 95% reduction in iridium usage isn’t just an improvement – it’s potentially disruptive to the entire hydrogen economy. By dramatically reducing the manufacturing costs of PEM electrolyzers, Smoltek’s technology could help make clean hydrogen (produced from fossil-free electricity) economically competitive with the cheaper gray hydrogen currently produced from natural gas. This cost parity is essential for accelerating the energy transition, as economics – not just environmental concerns – will ultimately drive widespread adoption of hydrogen across all industries.

What many shareholders might not realize is that Smoltek Hydrogen is already working with several renowned industrial enterprises worldwide who are at the initial ”fuzzy front end” stage, with some having already purchased samples from Smoltek Hydrogen.

”We’re actively engaged with multiple industrial enterprises globally, but strict confidentiality requirements at these early stages prevent us from disclosing specifics,” Ellinor explains. ”This is standard industry practice – companies in stage one, and often even stage two, typically prohibit their technology partners from publicly discussing the collaboration. This silence doesn’t indicate inactivity; quite the opposite – it’s a sign of serious industry engagement.”

”Our recently announced strategic collaboration with Heraeus is a perfect example,” Ellinor notes. ”We’ve been working with them for some time, but it’s only now, as we enter a more formalized partnership stage, that we can publicly share this information. This announcement represents a significant milestone, demonstrating that our technology has successfully progressed through the initial evaluation stages.”

Smoltek Hydrogen has established dialogue with key players across the PEM value chain, including both major electrolyzer manufacturers and their strategic suppliers. After initial technology presentations, several of these industry stakeholders have progressed to more detailed technical discussions and sample evaluations, positioning them at the advanced stages of the initial evaluation phase. According to Ellinor Ehrnberg, the feedback from these interactions has been highly encouraging, with clear indications that several companies are preparing to take their assessment of Smoltek Hydrogen’s technology to the next level.

”This is a great sign. It means they see the potential of our technology and are ready to go deeper. They’ve played around with our material in the lab and now they want to take the next step,” says Ellinor Ehrnberg. ”And that’s where it’s really important for us to show that our technology delivers what we promise and that we can deliver what they need. We start by delivering small samples, 2×2 centimeters, and show that it works. Then we take it further.”

And what happens when they move into the trial phase?

”Then we deliver larger samples, typically 5×5 centimeters, and work closely with them to help them evaluate the technology. It’s about identifying and managing the technical risks and adapting the technology to their specific needs,” explains Ellinor.

Industry experts have taken notice of Smoltek Hydrogen’s approach. Dr. Felix Büchi recently highlighted the uniqueness of Smoltek Hydrogen’s solution – specifically how they can prepare a very low amount of iridium with high surface area on the PTL.

”When experts like Dr. Büchi validate what we’re doing, and you pair that with how desperately the industry needs to solve the iridium problem… well, things can move pretty quickly,” Ellinor Ehrnberg says. ”And what’s encouraging for us is that we’re not just waiting for some big payday down the road – we will generate increasing revenue all along the way.”

How so?

”Well, we are already selling consulting services and prototypes. They need our expertise to see how they can incorporate our technology into their products. And we will also start selling more and more of our cell material, PTE,” explains Ellinor Ehrnberg. ”In addition, supplier development agreements are an important part. We enter into agreements with manufacturers where we are paid to help them adapt our technology to their specific needs and volumes.”

How long does it usually take for a PEM manufacturer to go through the different phases?

“It really depends on what’s driving the market. When you’ve got a solution to a serious problem like the iridium shortage, things can move much faster than usual. We’re seeing incredible momentum in green hydrogen right now – manufacturers know they need to solve this, and they can’t wait around forever. I’d say we’re in the right place at the right time with our technology. We need to get it right, though. And we must ensure we can scale up gradually as market demand grows,” says Ellinor Ehrnberg.

While development processes follow established frameworks, Ellinor emphasizes that actual progression can accelerate dramatically when a technology addresses urgent market needs.

”The pace of development can vary greatly between different industrial enterprises,” Ellinor explains. ”When a technology offers a compelling solution to a critical market challenge – as our PTE technology does for iridium reduction – we often see traditional timelines compress significantly. Companies just can’t afford to move at a normal pace when their competitors might be racing to solve the same problem. We’re seeing this urgency firsthand in the green hydrogen space.”

Heraeus exemplifies this accelerated trajectory. ”Our collaboration with Heraeus has progressed at an impressive pace,” Ellinor notes. ”Their recognition of the strategic value of our PTE technology, combined with the market pressures to reduce iridium dependency, created the right conditions for a swift advancement to a formal partnership.”

This variable timing works in Smoltek Hydrogen’s favor, particularly given the global focus on sustainable energy solutions. ”We’re fortunate that our technology addresses a critical bottleneck in the green hydrogen production chain at precisely the moment when the world is undergoing a necessary energy transition,” explains Ellinor. ”This alignment creates a sense of urgency among potential partners that can significantly accelerate the typical development timeline.”

The reality today is that many industrial enterprises are moving much faster than in previous decades. Companies like Apple, NVIDIA, and even hydrogen companies like PowerCell have demonstrated the ability to rapidly develop and integrate new technologies when they see a clear strategic advantage.

A major strength in Smoltek Hydrogen’s approach is how thoughtfully they’re planning their production growth. Rather than rushing to build large-scale manufacturing before the market is ready, Smoltek Hydrogen is taking a more measured approach that makes financial sense.

”We’re being smart about how we scale up,” explains Ellinor Ehrnberg. ”Building a huge factory right now would tie up money we could use more effectively elsewhere. Instead, we’ve developed a flexible approach where we can start smaller and expand as customer demand grows. We begin in the lab, move to pilot production, and then scale to industrial manufacturing when we have solid orders. This way, we’re investing at the right time and pace.”

This strategy gives Smoltek Hydrogen important advantages in an emerging market. By staying nimble and adjusting production capacity as the market develops, they can respond quickly to opportunities while managing risks. The team has identified the key technological stages to scale production when needed, without overcommitting resources too early in the process.

Ellinor Ehrnberg emphasizes that Smoltek Hydrogen is not just a material supplier, but a partner to the major PEM manufacturers:

”We want to be part of the whole journey and help our customers to integrate our technology into their products. It’s not just about selling a material, it’s about building long-term relationships and sharing our expertise. We have unique knowledge in this area.”

This collaborative approach is essential for successfully implementing such advanced technology.

”And we’re open to learning from them too – they know their products and processes inside out. By working together, we can find the best solution. The key is showing that we’re a reliable partner who can deliver what they need, when they need it. This business requires patience and persistence, but we’re in it for the long run.”

How does Smoltek Hydrogen turn this approach into tangible results? The company benefits from President Ellinor Ehrnberg’s expertise – with her PhD in Technology and Corporate Strategy from Chalmers University of Technology and practical experience from companies like SKF and Rise. This background has directly shaped Smoltek’s market strategy.

“Our development roadmap is carefully synchronized with where our potential customers are in their own processes,” explains Ellinor. “We’re prepared to meet manufacturers at whatever stage they’re in – whether they’re just beginning to explore solutions to the iridium problem or are ready for deeper integration.”

This thoughtful alignment means Smoltek can generate revenue throughout the journey – from initial sample sales and consulting in early stages to increasingly substantial development agreements as relationships mature. The Heraeus partnership exemplifies how rapidly progression can occur when technology and market needs align perfectly.

“What’s especially promising is how our commercial opportunities grow at each stage,” notes Ellinor. “We start with modest revenue from samples and consulting, but as we progress to formal agreements and joint development projects, the commercial relationships become much more substantial.”

In this article, we have explained how Smoltek Hydrogen is matching the pace of the major PEM electrolyzer manufacturers, how they are scaling up production over time, and how multiple industrial enterprises are already engaged at various stages of development with Smoltek Hydrogen. We’ve also clarified why you might not hear about all collaborations due to confidentiality requirements in early development stages, and how the recent Heraeus announcement exemplifies successful progression through the development process.

In our next article, we’ll explore how truly disruptive innovations like Smoltek’s PTE technology can dramatically accelerate traditional development timelines, and why this creates a strategic decision point for industrial enterprises that separates market leaders from those who fall behind.

Now it’s your turn to share your thoughts. Leave a comment or ask a question in the comments section of our LinkedIn post on this article. We promise to answer and share as much as we can, taking into account confidentiality agreements and what is allowed by laws and regulations for public companies.

Your data will be handled in compliance with our privacy policy.