Sign up for our newsletter!

Your data will be handled in compliance with our privacy policy.

Your data will be handled in compliance with our privacy policy.

Latest news from Smoltek.

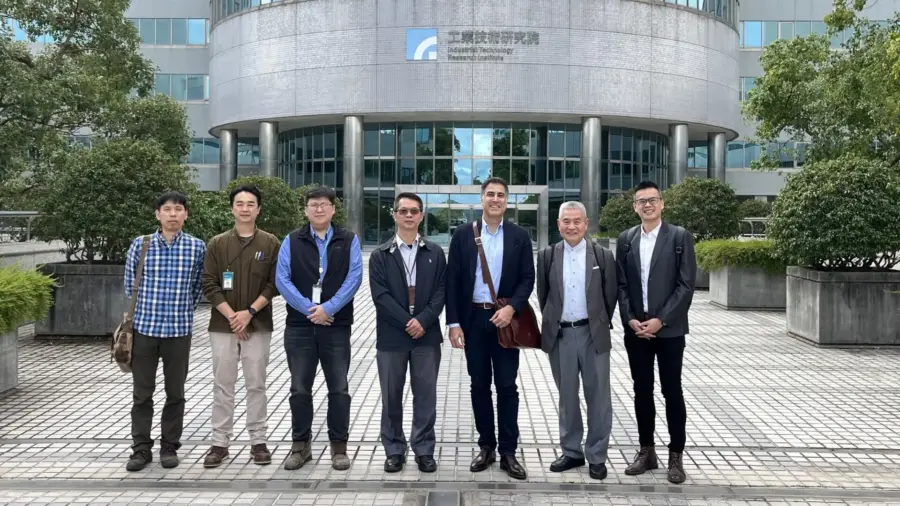

Smoltek Semi and Taiwanese Industrial Technology Research Institute (ITRI) are discussing a collaboration to set up a pilot line for fabrication of CNF-MIM capacitors in Taiwan as part of getting ready for mass production.

Smoltek Hydrogen has been invited to participate in a Scandinavian delegation of technology leading hydrogen companies for a round-trip to Germany’s energy-producing regions in Rhur and central Germany.

A leading automotive manufacturer is interested in our technology for hydrogen solutions and has ordered number of prototypes of Smoltek Hydrogen's nanostructure coating modified for fuel cells.

Dr Felix N. Büchi, a leading specialist in PEM technology, has evaluated Smoltek Hydrogen’s ground-breaking technology for the Porous Transport Electrode (PTE) for PEM electrolyzers.

Smoltek has published the company's interim report for the third quarter 2024. The report, in both Swedish and English, can be found on the company's website under the Investors tab.

Smoltek Hydrogen has received an order to carry out a small preliminary study of a special type of electrochemical cell, adapted for electronic devices. This could open new business opportunities for Smoltek.

Smoltek Semi has developed a new process, known as zapping, that reduces the number of steps required to manufacture test capacitors.

Smoltek has been awarded a new patent within the hydrogen business area. The patent discloses an invention for corrosion protection of nanostructures with non-noble metal oxides on the anode in PEM water electrolysis, improving the durability and efficiency of electrodes with low iridium loading.

Smoltek Semi has spent the last nine months working intensively on a project to develop a new dielectric stack for the CNF-MIM capacitor technology resulting in a 230% boost in capacitance density.

Smoltek is a Gothenburg-based materials technology company that specializes in research and development of applications based on carbon nanofibers, which can create new products with revolutionary properties.

Smoltek Hydrogen has made a significant technological breakthrough. The R&D team has successfully grown carbon nanofibers (CNFs) over an A4-sized area, marking the first time such a large CNF-covered material sample has been fabricated. This breakthrough is a crucial step towards industrial scalability of carbon nanofiber coating, which is a key step in developing the porous transport electrode for PEM electrolyzers and similar solutions for fuel cells being developed by Smoltek Hydrogen.

Smoltek has been awarded a new patent in the Discrete CNF-MIM patent family. The protected innovation in this patent family discloses a discrete capacitor component based on our CNF-MIM technology. This also brings our IP portfolio to comprise 91 granted patents.