Sign up for our newsletter!

Your data will be handled in compliance with our privacy policy.

Your data will be handled in compliance with our privacy policy.

Advanced nano- and microelectronics are at the core of tomorrow’s hardware engineering. At Smoltek we are pioneering carbon nanotechnology that enables manufacturing of the next-generation solutions for the semiconductor industry. Currently the focus is on a new type of carbon nanofiber-based capacitor that fits in the extremely miniaturized packaging architectures being developed by chip manufacturers.

Miniaturized integrated circuit packaging types are different types of protective packages that isolate semiconductor components from the effects of physical impact and corrosion. There are several types of integrated circuit packages, and they become more complex in architecture the smaller they get.

In 1970, chip manufacturers managed to fit 1,000 transistors per chip. Today, over 50 billion have been squeezed in – on a chip the size of a thumbnail. And this development only continues, as more data must be processed at the same or faster pace. In addition, more functions are added on the chip, all while the space in these miniaturized packaging types remains the same – or decreases. This development also requires that the capacitors take up less space and that they can be placed closer to the active chip – and at the same time have the same or better performance.

More complex chips require a new generation of capacitors

New advanced chips consist of several systems. These chips have more features and better performance. To secure the power supply in these tightly miniaturized circuits and reduce losses in the systems – which is essential for the overall increases in performance – the capacitors must be extremely small and thin, so that they can be placed closer to the processor than is currently possible.

This is exactly what Smoltek is developing – a new capacitor technology that meets the semiconductor industry’s demands for next-generation capacitors. Our technology offers several properties that are crucial for the development of the new capacitor generation. Among other things, extremely high capacitance per unit area and extremely low electrical losses. The capacitors can also be placed in direct connection to the systems they are to support.

The benefit for you and me is that we get more and better functions in the mobile phone.

Regards, Smoltek CNF-MIM capacitor technology

CNF-MIM – Next-gen capacitors

Based on our proprietary nanotechnology platform we have developed a new capacitor technology that fulfills the demands of high-performance application processors for the mobile phone market. We call the product line CNF-MIM – Carbon Nano Fiber-Metal Insulator Metal capacitors – a new breed of capacitors that offers unparalleled metrics for decoupling capacitors. And that fits in the increasingly confined spaces of next-gen semiconductor chips.

Today, we at Smoltek are alone in the world to offer a carbon nanofiber technology that enables the combination of extremely high electrical performance in an extremely miniaturized capacitor device.

Håkan Persson, CEO of Smoltek

The decoupling capacitor explained

A decoupling capacitor is used in electronic devices to reduce high frequency noise and disturbances in the power supply. It is a key device in e.g., application processors (like the main processor in a mobile phone). However, to reduce losses at high frequencies, it is important to be able to place the capacitor as close to the active chip as possible, which requires both extreme thinness and high capacitance density (which simply explained can be said to be the horsepower of the capacitor).

Our technology makes it possible to place the capacitor closer to the processor, which in turn reduces the losses in the system and enables better performance in the next generation chip.

Håkan Persson explains

For the chip manufacturers, the benefit of Smoltek’s technology is that they can place the capacitors closer to the active chip and thus reduce the losses in the system. The CNF-MIM technology also enables flexibility for the chip manufacturers, partly in terms of the performance parameters they want, partly in terms of how they can design the capacitor component in their system as the technology has no restrictions regarding compatible materials.

The benefit for you and me is that we get more and better functions in the mobile phone.

Market for CNF-MIM capacitors

Smoltek’s CNF-MIM capacitors mainly compete with silicon-based so-called trench capacitors. Smoltek uses the substrate to grow the fibers on top, unlike the competitors who use the substrate to etch the active area. In other words, Smoltek has an additive and the competitors a subtractive process leaving them with the requirement of using the substrate to increase a larger active area.

Our CNF-MIM technology has the potential to offer an ultra-thin capacitor with the same, or higher, capacitance density at a lower cost than our competitors.

Håkan Persson conludes

And as stated, at the IMAPS Device Packaging Conference in Phoenix, Arizona, on March 3, 2020:

The single most important question for semiconductor packages for mobile phones is: How thin can we make it?

Christian Hoffmann, Principal Engineer at Qualcomm

Put in context, this means that the continued miniaturization of semiconductor packages needs much thinner capacitors compared to what today’s conventional technology can handle.

Your data will be handled in compliance with our privacy policy.

News

November 20, 2025

We have launched a podcast about materials technology and investments in general and our disruptive carbon nanotechnology in particular.

News

November 17, 2025

Smoltek Semi is currently optimizing the company’s advanced PECVD system to ensure implementation of its most recent technological innovations in CNF synthesis, enabling compliance with stringent customer requirements, prior to installation at ITRI in Taiwan.

News

November 5, 2025

Smoltek Semi has reached an important technical milestone in the development of the company’s carbon fiber-based CNF-MIM technology. The capacitors have successfully passed a 1,000-hour high-temperature durability test, confirming the robustness of the technology for advanced applications.

News

October 24, 2025

Smoltek Semi has acquired a plasma-enhanced Atomic Layer Deposition (ALD) system to implement its advanced dielectric stack on carbon nanofibers. The system will significantly reduce the iteration time of coating processes while enabling innovation and IP generation in dielectric stack technology for carbon nanofiber electrodes.

News

October 16, 2025

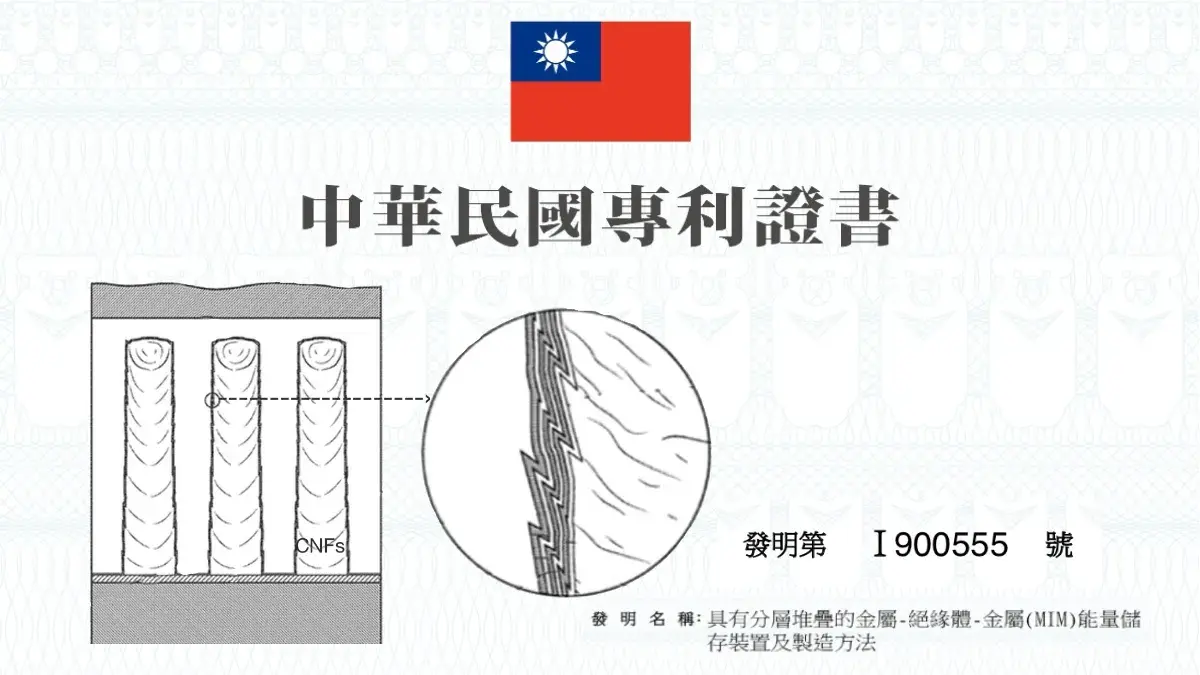

Smoltek has been awarded another patent in the Multilayer Cap patent family – an innovation that can double or triple the capacitance density of our CNF-MIM capacitors. This is a key factor for Smoltek's business and technology development.

News

September 17, 2025

Smoltek Semi has successfully participated in Semicon Taiwan 2025, invited by their strategic partner ITRI.