Sign up for our newsletter!

Your data will be handled in compliance with our privacy policy.

Your data will be handled in compliance with our privacy policy.

Smoltek has achieved very successful test results of the company's disruptive cell material for PEM electrolysers. Prototypes with only 0.5 mg of iridium per square centimeter produce as much hydrogen as a standard material with 2.5 mg of iridium per square centimeter.

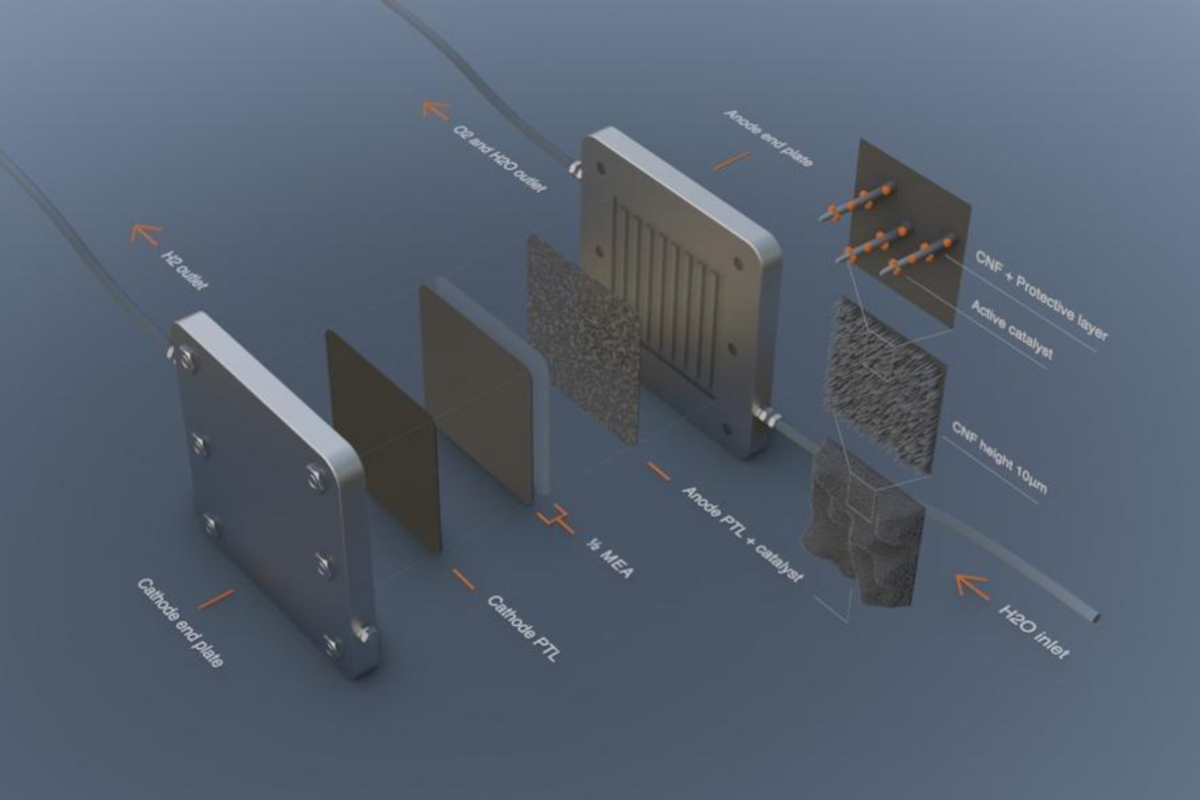

Within the hydrogen business area, Smoltek develops a cell material for PEM electrolyzers (Smoltek ECM) with a goal to minimize the amount of the rare precious metal iridium in the electrolyzer cell (the iridium catalyst loading). The electrolyzers will thus become much cheaper to manufacture. The reduced amount of iridium per electrolyzer will also help enable global scale-up of PEM electrolyzers, which are essential for the production of fossil-free hydrogen.

The results of these tests have been verified, and they show that with a calalyst load of only 0.5 mg of iridium/cm2, Smoltek’s prototypes produce the same amount of hydrogen as a conventional cell does with 2.5 mg of iridium/cm2.

The improvement is due to the development of the company’s unique cell material and the three-dimensional nanostructure the corrosion-coated carbon fibers provide. The next step is to start tuning various technical parameters to further improve the technology and reach the goal of 0.1 mg iridium per square centimeter.

“This is an incredibly pleasing result for us. Already today, the iridium price is up to SEK 2 million per kilogram and is expected to rise to SEK 8–10 million per kilogram before the end of the decade. This shows that our concept is extremely strong.”

Ellinor Ehrnberg, President of Smoltek Hydrogen

The prototypes, developed by the group company Smoltek Hydrogen in collaboration with a large industrial manufacturer of electrolyzers materials (components), have been tested by a prominent German technical institute. Smoltek’s cell material have been assembled into prototypes (demonstrators) of complete electrolyzer cells and tested these against conventional cells.

The tests indicate that the same capacity is reached with the Smoltek cell material as with a standard material, which in this case contains five times more iridium than the Smoltek material. This means that Smoltek Hydrogen’s sub-goal of getting down to 0.2 mg of iridium per square centimeter is within reach. The next development step is to start tuning various technical parameters to get closer to the goal of only needing 0.1 mg iridium per square centimeter.

In addition, the initial long-term tests have also yielded positive results where Smoltek’s prototypes have passed a 1,000-hour test without degrading. It shows that the corrosion-resistant coating prevents the carbon nanofibers from breaking down in the highly corrosive environment of the anode side where the water maintains a pH value of 0.

Facts, Smoltek ECM (Electrolyzer Cell Material):

Smoltek’s proprietary material for electrolyzers is a three-dimensional nanostructure-based coating developed to radically reduce the iridium catalyst loading and increase proton throughput in an electrolyzer cell.

Your data will be handled in compliance with our privacy policy.

News

November 20, 2025

We have launched a podcast about materials technology and investments in general and our disruptive carbon nanotechnology in particular.

News

November 4, 2025

Smoltek Hydrogen has received an order for samples of low iridium-load Porous Transport Electrodes (PTE) for PEM electrolyzers. The electrodes will be used in a joint development project with Heraeus Precious Metals, a global leader in precious metals.

News

October 30, 2025

Smoltek Hydrogen recently participated in the Hydrogen Technology World Expo 2025 in Hamburg, Germany – the world’s largest industry event for innovation in hydrogen and electrolysis technology. Ellinor Ehrnberg, President of Smoltek Hydrogen, was invited to a panel discussion on the topic “Overcoming the Key Obstacles in Electrolyzer Expansion”

News

June 12, 2025

Smoltek Hydrogen is developing Smoltek PTE – a proprietary porous transport electrode based on carbon nanostructures, which is intended to meet the requirements of next-generation PEM electrolyzers for the production of fossil-free hydrogen.

News

May 20, 2025

Smoltek has been awarded a new patent within the hydrogen business area. The patent discloses a method for depositing conformally coated catalyst support for the PTL (porous transport layer) that provides both high catalytic activity and additional corrosion protection.