Sign up for our newsletter!

Your data will be handled in compliance with our privacy policy.

Your data will be handled in compliance with our privacy policy.

Smoltek Semi develops ultra-thin high-performance capacitors for AI and advanced electronics. The semiconductor market for these types of capacitors is rapidly increasing, driven by the need for higher capacitance density and superior high-frequency performance.

Smoltek’s CNF-MIM technology combines high capacitance density and low parasitic inductance with ultra-compact form factor delivered on various substrates. By using a single dielectric stack for capacitor manufacturing Smoltek enables efficient power management for AI, High-Performance Computing, and premium electronics at lower production costs.

Our offer

The most demanding electronic applications require next-generation, ultra-thin capacitors that deliver high capacitance density, exceptional high-frequency performance, robust temperature stability, and very low losses. Smoltek Semi provides the foundational technology to meet these demands.

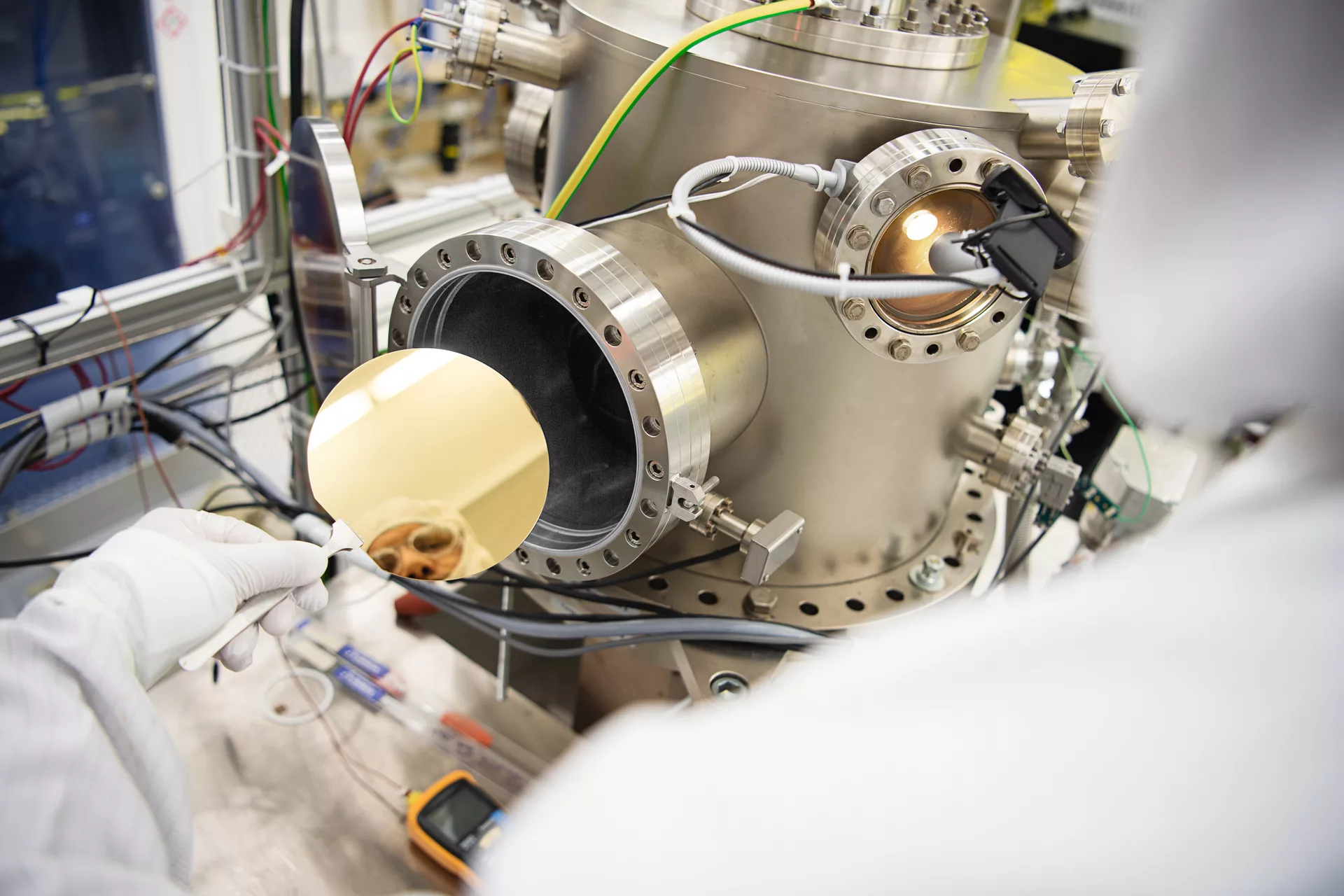

We use carbon nanofibers (CNFs) to create an immense 3D surface for metal-insulator-metal (MIM) capacitors. Unlike DTC, our process works on more than just silicon and uses only a single dielectric stack, increasing flexibility while reducing manufacturing complexity and cost. These features make our CNF-MIM technology an ideal solution for the world’s most demanding applications.

AI workloads and high-performance computing (HPC) demand exceptional power delivery with up to eight times more capacitors than traditional servers. CNF-MIM technology provides superior capacitance density where conventional MLCCs reach their physical limits.

Space inside premium smartphones is a critical constraint. CNF-MIM’s ultra-thin profile delivers high capacitance density, enabling placement closer to the processor. This proximity is key to improving power integrity and unlocking peak performance.

Wearables are defined by their spatial constraints. CNF-MIM’s ultra-thin profile is a key enabler, offering advanced integration methods like embedding capacitors directly in the substrate. This saves critical space, allowing for thinner designs and larger batteries.

High-frequency 5G applications require exceptional stability and low losses. CNF-MIM delivers enhanced stability for high-frequency communication and RF circuits with minimal signal degradation where traditional capacitors introduce unwanted impedance.

Advanced driver assistance systems and EV electronics face vibration, temperature variations, and strict safety requirements. CNF-MIM technology provides robust performance for ADAS sensors and power management with automotive-qualified reliability.

The defense and aerospace industry requires components that deliver exceptional reliability in the most demanding conditions. CNF-MIM technology provides robust, high-performance solutions for critical applications such as radar, communication systems, and avionics.

About us

Our approach combines 20+ years of carbon nanotechnology research from Chalmers University of Technology, patent protection across major semiconductor markets, and a team where most R&D staff hold Ph.D.s in nanotechnology and semiconductor processes.

Smoltek was founded in December2005, as a spin-off from research at Chalmers University of Technology with a focus on precisely controlling carbon nanostructure growth. Since then, Smoltek has developed this technology into practical manufacturing processes. Today, Smoltek Semi applies this proven technology platform to meet the electronic industry’s need for ultra-thin, high-density decoupling capacitors.

Smoltek’s intellectual property portfolio includes over 120 patents (granted and pending) covering core carbon nanotechnology, component structures, and manufacturing processes. This protection spans major markets including the US, Europe, China, Japan, and Korea, with a substantial focus on the semiconductor industry.

Most of our R&D team holds Ph.D.s in materials science, nanotechnology, or semiconductor engineering. Our technical depth spans from fundamental carbon nanotube growth to integration in semiconductor manufacturing.

Our process

We work with industrial partners through a structured development process that aligns with how large enterprises evaluate and integrate new technologies. Each stage builds on the previous one, with clear technical and commercial milestones.

We provide engineering samples of our CNF-MIM capacitors for your initial testing. Your technical team gets direct access to our R&D engineers to discuss performance data, manufacturing parameters, and potential applications. This stage typically involves lab-scale testing to validate basic functionality and compatibility.

Following positive initial results, we establish a formal collaboration agreement. This can take the form of a joint development project, feasibility study, or technical advisory agreement. We conduct detailed analysis of technical requirements, manufacturing integration, and commercial viability specific to your applications.

With proven technical and commercial feasibility, we forge a licensing partnership. You gain access to our IP portfolio, manufacturing know-how, and design documentation. Your engineering teams can then perform detailed design work and integrate our technology into your production processes.

Our relationship continues through commercial production. Your team retains access to our R&D specialists for technical support, process optimization, and co-development of next-generation solutions. This ensures continuous improvement and helps address evolving requirements.

Features

As electronic components shrink while performance demands increase, conventional capacitors face fundamental limits. Our CNF-MIM technology overcomes these limits by building capacitors on a microscopic 3D scaffolding of carbon nanofibers. This immense surface area, created within an ultra-thin profile, is what enables the unique combination of performance and miniaturization detailed below:

The first generation of our capacitors, the “CNF-MIM Gen-One,” has a target capacitance density of 250 nF/mm². In future generations we aim to exceed 1,500 nF/mm² in an ultra-thin profile.

Engineered for high-speed systems, our capacitors ensure stable power delivery to advanced processors. With exceptionally low inductance (ESL < 2 pH) and resistance (ESR < 50 mΩ), they are a key advantage for power integrity.

Our capacitors ensure power is used effectively, with an ultra-low leakage current of less than 100 pA at 2 V and minimal resistive losses. This superior efficiency is crucial for extending battery life in compact, power-sensitive devices.

We deliver reliable performance, guaranteeing stability for demanding applications. Our technology shows only a ~2.5% capacitance change when tested up to 125°C, ensuring your system performs as designed across wide temperature ranges.

Frequently asked questions

We have demonstrated 1 µF/mm² (1,000 nF/mm²) capacitance density with an active layer thickness of just 6 µm. This combination of high capacitance and ultra-thin profile makes the technology suitable for under-chip integration where height constraints are critical. Prototypes using our ZrO₂–Al₂O₃ dielectric stack have passed temperature and voltage stress testing. Our development roadmap targets 3,000 nF/mm² in future generations.

We operate a fabless model with established manufacturing partnerships. ITRI handles front-end wafer processing while Tong Hsing provides back-end assembly and testing. Our additive process uses standard semiconductor equipment and can be integrated into existing production lines. We provide complete technology transfer packages including process specifications and quality control procedures.

Our licensing model includes three components: upfront licensing fees for patent access, non-recurring engineering fees for integration support and qualification assistance, and production royalties based on net sales of products incorporating our technology. The specific terms are structured based on your application and volume requirements.

We start with discrete capacitors for immediate market applications. The development roadmap includes embedded capacitors within chip packaging substrates, followed by on-chip integration for placement close to processors. Each step requires specific technical adaptations but builds on the same core CNF-MIM platform.

Our R&D team works directly with your engineering teams throughout the integration process. This includes design optimization for your specific applications, process parameter adjustment, qualification testing support, and ongoing technical consultation. We maintain this relationship through production and future product development.

Evaluating new capacitor technology requires understanding performance specifications, manufacturing requirements, and integration pathways. Here are answers to common questions about CNF-MIM technology from our technical discussions with industry partners.

We actively seek partnerships with capacitor manufacturers and electronics companies to bring CNF-MIM technology to market. Our R&D team works directly with prospective partners to evaluate commercial opportunities.

Contact usOur Promise

We understand that adopting disruptive technology requires transparency and predictability. Our partnership approach focuses on working together through each technical and commercial milestone in a disciplined and structured way.

You don’t need to commit to a full-scale license right away. We recommend starting with specific projects, such as feasibility studies or joint development work, to address particular technical issues. This approach enables your engineering teams to validate our technology within your existing systems and applications before making larger commitments.

We cover all aspects of CNF-MIM development, providing support throughout your evaluation and implementation process:

This complete capability means we can support your project from initial samples through commercial manufacturing.

Whitepaper

A deep dive into the technology behind CNF-MIM – get your free copy from Smoltek. This is not a marketing brochure, but a 10-page technical whitepaper authored by our nanotechnology researchers. Learn about the fundamental properties of carbon nanofibers, the catalytic growth process, and the applications enabled by the technology.

Download