Sign up for our newsletter!

Your data will be handled in compliance with our privacy policy.

Your data will be handled in compliance with our privacy policy.

Smoltek Hydrogen is attending the joint international meeting of Electrochemical and Solid-State Science. The meeting is arranged by Electrochemical Society Japan, Electrochemical Society Korea and the PRiME 2024/246th ECS Meeting and will be held in Honolulu, HI.

Smoltek Hydrogen is progressing towards enhancing water electrolyzer (PEMWE) performance with 0.1 mg/cm² iridium loading using our innovative porous transport electrodes (PTEs). By optimizing PEMWE assembly and refining the operating conditions for PTEs, we are rapidly approaching the US Department of Energy (DOE) targets.

Sankar Sasidharan, Senior Scientist Electrochemistry

Enabling green hydrogen production on GW scale

Currently, we have achieved performance of 2.5 A/cm² at less than 2V (~80% cell efficiency), with an iridium loading of 0.2 mg/cm². Our current focus is on addressing the knowledge gap in low-iridium loading for the anode catalyst layer (ACL) with our PTEs, particularly regarding proton/electron and water/gas transport and ensure stable operation for more than 1,000 hours under industrial conditions. The results will help us to run durability tests at an iridium loading of 0.1 mg/cm² and surpass the previous record.

Sankar Sasidharan, Senior Scientist Electrochemistry

Smoltek Hydrogen presents: Improving Performance of PEM Water Electrolysis Utilizing Nanofiber-Enhanced Porous Transport Electrodes with Low Iridium Content

When: Wednesday, 9 October 2024, 14:40–15:00 Hawaii Standard Time (HST)

Where: Room 312 (level 3, Hawaii Convention Center)

Conference code: I01-B2828

Moreover, the recent breakthrough with A4-sized substrates has further accelerated Smoltek Hydrogen’s vision of enabling green hydrogen production on a GW scale with lower precious metal loadings.

The Prime 2024 (246th ECS) event brings together the most active researchers in academia, government, and industry to engage, discuss, and innovate in the areas of electrochemistry and solid state science and related technologies.

- See you in Honolulu, October 6–11!

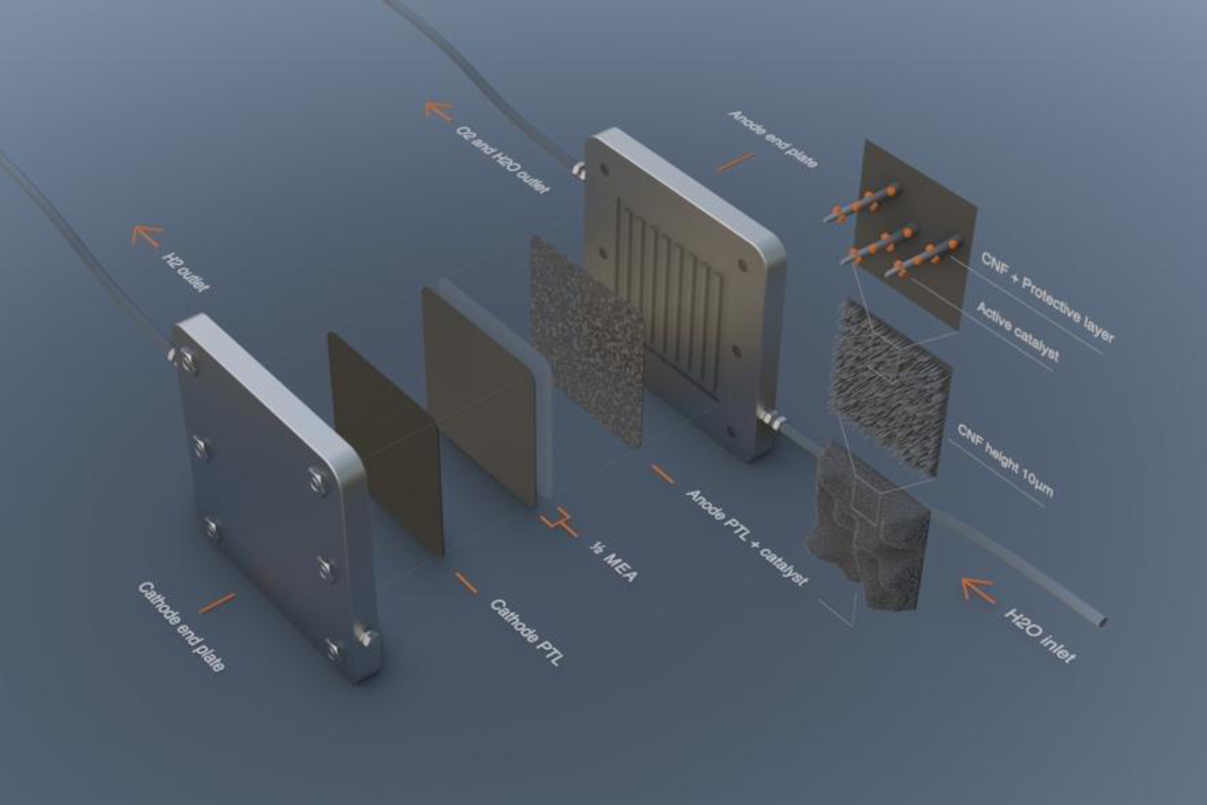

Smoltek Hydrogen PTE technical scope: The low electrical resistivity and high mechanical strength indicate why corrosion coated nanofibers are an attractive catalyst support material. The solution offered by Smoltek Hydrogen takes full advantage of the exceptional nanofiber properties on a PTL (above illustration). This method ensures full contact between the nanofibers and the PTL while providing a high surface area substrate and catalysts can then be deposited on top of this substrate. The vertical orientation of the nanofibers facilitates coating of the surface with additional layers of material, such as corrosion protection layers or catalyst particles.

Your data will be handled in compliance with our privacy policy.