Sign up for our newsletter!

Your data will be handled in compliance with our privacy policy.

Your data will be handled in compliance with our privacy policy.

Smoltek Semi has spent the last nine months working intensively on a project to develop a new dielectric stack for the CNF-MIM capacitor technology resulting in a 230% boost in capacitance density.

The first phase of this project has now concluded successfully, demonstrating significant improvements over the previous generation of dielectric stacks. The new stack, based on zirconium oxide, will be integrated into future generations of CNF-MIM capacitors. The prior stack, made from hafnium oxide, was utilized in the Gen Zero capacitors.

The newly developed dielectric stack is a blend of two oxides: a high‑k oxide to boost capacitance density, and an oxide that serves as a barrier against charge movement, thus minimizing current leakage.

Farzan Ghavanini, CTO at Smoltek.

During the first phase, Smoltek Semi focused on parallel plate capacitors, depositing the dielectric stack on flat surfaces between two parallel electrodes. Performance measurements were carried out at the wafer level and after the devices were transferred and mounted onto PCBs. The results revealed an extraordinary 230% improvement in capacitance density compared to the Gen Zero dielectric stack, while another critical performance metric, leakage current, showed a 50% reduction.

The results have been outstanding, both in terms of performance metrics and reproducibility. I’m particularly excited about the exceptional reproducibility achieved during the first phase, where we reached a fabrication yield of 100%.

Farzan Ghavanini

The devices mounted on PCBs have now been sent to Yageo who is supporting Smoltek with reliability testing and further characterization.

Your data will be handled in compliance with our privacy policy.

News

November 20, 2025

We have launched a podcast about materials technology and investments in general and our disruptive carbon nanotechnology in particular.

News

November 17, 2025

Smoltek Semi is currently optimizing the company’s advanced PECVD system to ensure implementation of its most recent technological innovations in CNF synthesis, enabling compliance with stringent customer requirements, prior to installation at ITRI in Taiwan.

News

November 5, 2025

Smoltek Semi has reached an important technical milestone in the development of the company’s carbon fiber-based CNF-MIM technology. The capacitors have successfully passed a 1,000-hour high-temperature durability test, confirming the robustness of the technology for advanced applications.

News

October 24, 2025

Smoltek Semi has acquired a plasma-enhanced Atomic Layer Deposition (ALD) system to implement its advanced dielectric stack on carbon nanofibers. The system will significantly reduce the iteration time of coating processes while enabling innovation and IP generation in dielectric stack technology for carbon nanofiber electrodes.

News

October 16, 2025

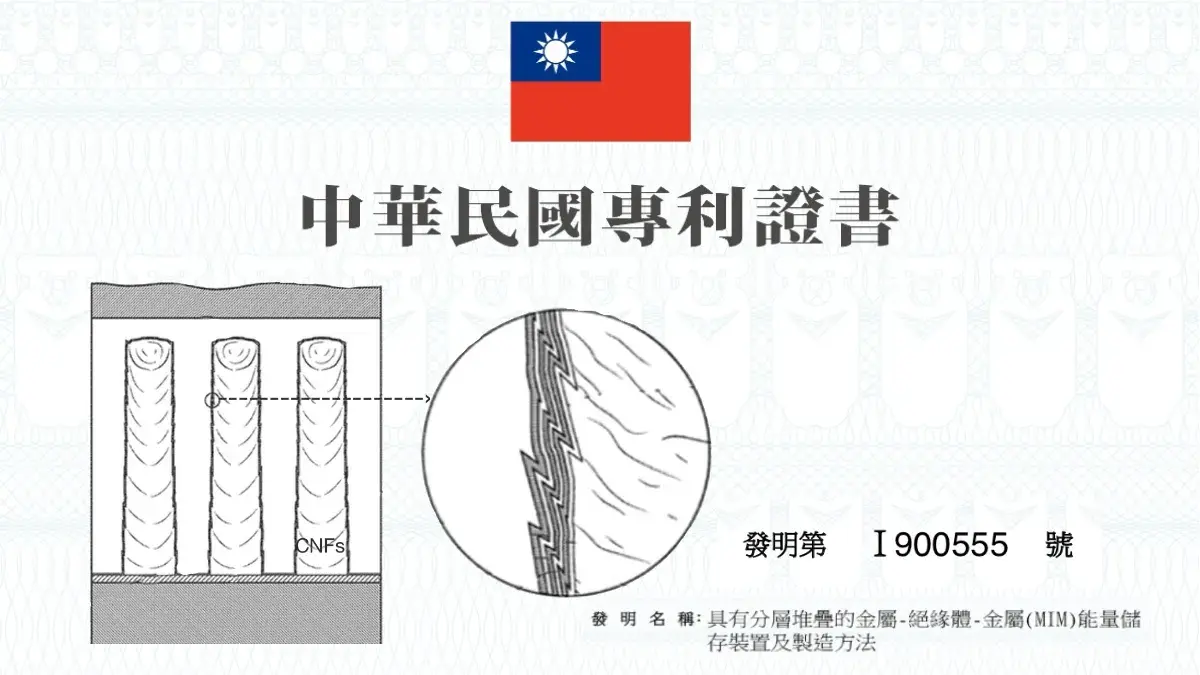

Smoltek has been awarded another patent in the Multilayer Cap patent family – an innovation that can double or triple the capacitance density of our CNF-MIM capacitors. This is a key factor for Smoltek's business and technology development.

News

September 17, 2025

Smoltek Semi has successfully participated in Semicon Taiwan 2025, invited by their strategic partner ITRI.