Sign up for our newsletter!

Your data will be handled in compliance with our privacy policy.

Your data will be handled in compliance with our privacy policy.

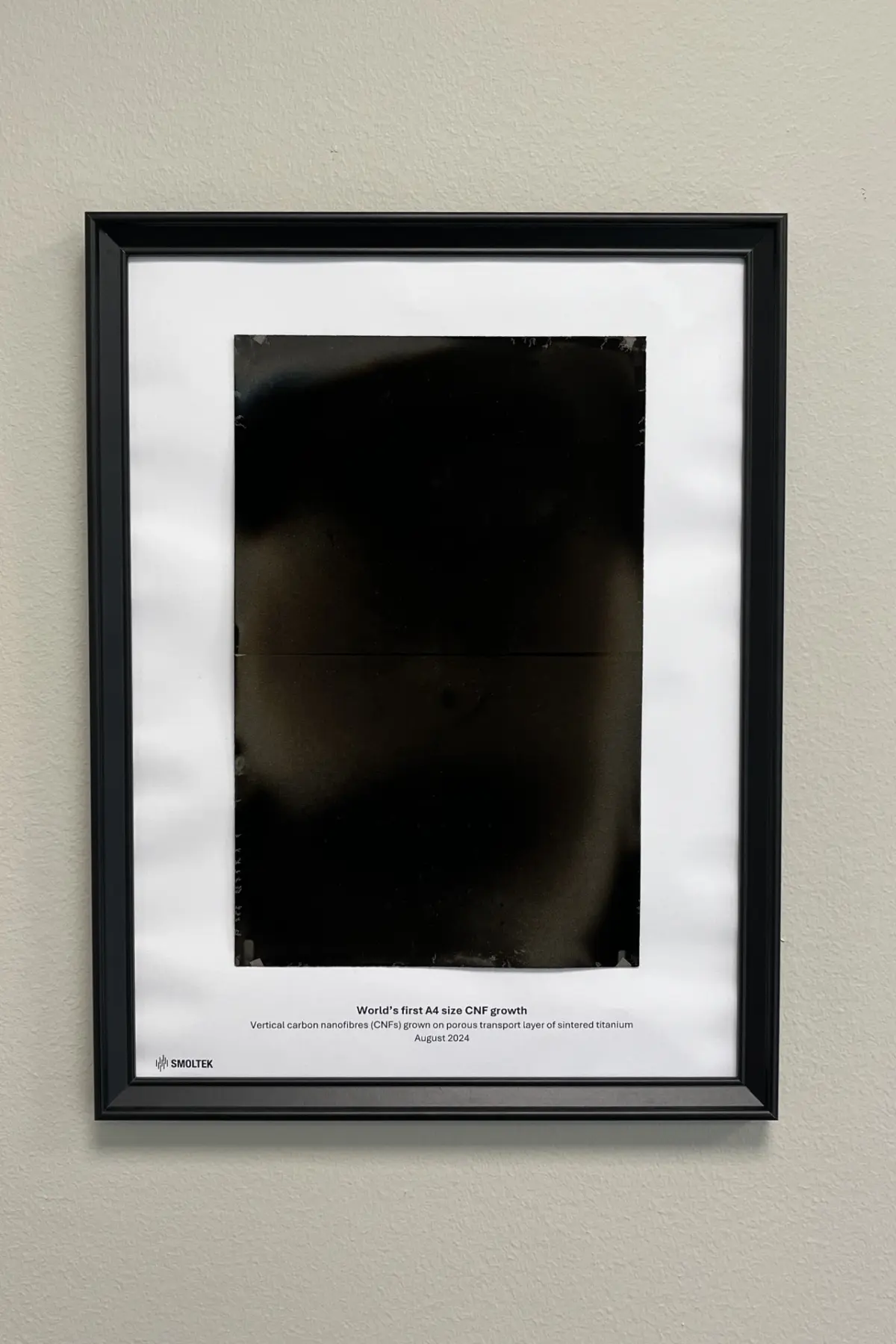

Smoltek’s recent breakthrough in growing carbon nanofibers (CNF) on an A4-sized area has caught the attention of researchers and industry experts alike. And rightly so! This achievement showcases Smoltek’s unique capabilities and valuable intellectual capital that must be protected. While patents are crucial for safeguarding this, fostering a company culture that empowers our employees is equally important. Let’s dive deeper.

Thomas Barregren • September 11, 2024

Smoltek has made a major breakthrough: successfully growing carbon nanofibers (CNF) on an A4-sized area. This achievement, detailed in our latest news and press release, underscores the significant value of Smoltek’s intellectual capital. As a shareholder or investor, it’s crucial to understand this value and how we protect it. This article explores what we have achieved, our strategy for monetizing it, the importance of our people, and how we are committed to preserving the intellectual capital they represent.

Almost two decades ago, Dr. Shafiq Kabir, founder of Smoltek, bought a used plasma-enhanced chemical vapor deposition (PECVD) reactor chamber from Chalmers University of Technology. It was needed for growing carbon nanofibers. The reactor chamber was the company’s first, affectionately known internally as “David.” Among the nerdier shareholders and investors, it’s known as the 6‑inch machine because it was used to grow carbon nanofibers on 6‑inch silicon wafers. It still can, but now “David” has been rebuilt to grow carbon nanofibers on a titanium substrate slightly larger than an A4 sheet (21×29.7 cm).

“With recent modifications, ‘David’ can now produce cell materials up to A4 size, a standard for industrial applications,” says Ellinor Ehrnberg, President of Smoltek Hydrogen. “This allows us to simultaneously produce up to 150 prototypes of 2×2 cm, or 24 prototypes of 5×5 cm, or a single prototype at A4 size.”

With a further modification planned, Smoltek will be able to produce up to 2,000 square meters of cell material per year.

Why would Smoltek produce 2,000 m² of cell material per year? There are no customers, after all.

Quite the opposite!

“In fact, customers are already knocking on our door,” Ellinor Ehrnberg, says. “While they may not order large quantities of cell material on day one, they rely on our cell material and expertise to develop their products.”

The development process, which typically spans 2–5 years, begins with prototypes that require cell materials in sizes of 2×2 cm and 5×5 cm. From there, they move to A4-sized cell material for building entire stacks, eventually leading to substantial orders for full-scale production.

At each stage—from initial prototypes to stacks and pre-series production—Smoltek generates revenue by supplying both the essential cell materials and the R&D services that enable customers’ development efforts. By the time these customers are ready for mass production, a volume factory will be capable of producing up to 200,000 m² of cell material per year, including sizes larger than 1 m².

One partner company exclaimed in amazement: ‘Is it true?!’

Ellinor Ehrnberg, President of Smoltek Hydrogen

To achieve A4-sized cell material production, Shafiq Kabir and others at Smoltek Hydrogen redesigned “David.” Among other things, the reactor chamber was given a larger top electrode and a larger heating plate. It sounds simple. But it is anything but.

“Shafiq is a wizard,” says Ellinor Ehrnberg. “No one outside Smoltek thought it possible to grow carbon nanofibers on a surface as large as A4. But with his unique expertise and systematic approach, Shafiq took on this seemingly impossible task and proved the naysayers wrong.”

Ellinor Ehrnberg continues:

“Since we published the news of our breakthrough, the result has attracted much attention from researchers and colleagues worldwide. One partner company exclaimed in amazement: ‘Is it true?!’ They were stunned by the result. It shows that Smoltek has a unique position in the market.”

Smoltek’s unique position stems from our highly qualified research and development and the intellectual property it generates. This expertise has solidified Smoltek’s position with its largest and longest standing investor as a company with significant, but not fully recognized, potential.

To protect this intellectual capital, Smoltek takes every possible measure, including securing exclusive rights to use the results of our R&D through patents. But even more crucial is Smoltek Hydrogen’s commitment to nurturing the team behind these remarkable achievements, ensuring they thrive and grow while making Smoltek an attractive employer that draws top talent worldwide.

Ellinor credits much of the company’s unique culture to the supportive and open-minded leadership of Shafiq Kabir and Fabian Wenger, Head of R&D.

“Fabian and Shafiq create an atmosphere where everyone feels valued,” Ellinor explains. “They are generous with their knowledge and always approachable, encouraging open discussion and collaboration. Their positive, inclusive approach brings out the best in everyone on the team.”

From the beginning, Smoltek Hydrogen’s co-founders, Ellinor Ehrnberg and Fabian Wenger, have been committed to building a safe and collaborative culture. No question is too trivial to ask and no idea is too outlandish to suggest. They believe in creating an open, welcoming environment where every employee feels safe, valued and appreciated.

This culture pays off through loyal employees who go the extra mile for the company and each other. A small but telling example is when the team framed the first A4-sized cell material and hung it in the office.

Your data will be handled in compliance with our privacy policy.