Sign up for our newsletter!

Your data will be handled in compliance with our privacy policy.

Your data will be handled in compliance with our privacy policy.

Clean hydrogen is on the rise. In many areas, it’s one of the few, if not the only, viable solutions to reduce CO2 emissions. The areas of use are many and varied. Providing a complete list is impossible, as new applications are emerging almost daily. To give you a sense of how diverse the market is, this post describes the five key areas of hydrogen applications, first at a glance and then in more detail. The post ends with a selection of applications from the different areas.

Thomas Barregren • February 21, 2024

The title of this post, Hydrogen is used for more than you think, is perhaps too presumptuous. Perhaps you know all the uses of hydrogen. But the fact is that if you take what is written in newspapers and said on the radio and television as any reflection of the uses of hydrogen, you are missing out on significant applications. In this article, we go through known and less-known uses of hydrogen. You may discover a new area that you didn’t already know about.

To avoid this blog post degenerating into an encyclopedia, where every application is explained in length and breadth, I must curb my desire to delve into the topic.

Therefore, this text doesn’t discuss different uses and applications, explain the pros and cons, or discuss history, technology, and examples. All of which could make for many interesting blog posts in the future. (Feel free to comment on LinkedIn about what you want to know more about). Instead, this is an incomplete catalog of more or less known uses of hydrogen.

But…

(This is important to keep in mind.)

I only mention application areas that are already commercially viable (e.g., fertilizers) or on the verge of commercialization with solid financial backing (e.g., e‑fuel). I omit any odd, esoteric, or futuristic uses.

Right now, there is a gold rush in the hydrogen field. Everyone wants to strike gold with hydrogen. Of course, not everyone will succeed. But frankly, that’s not a threat to the ambition to reduce CO2. On the contrary, the more people try, the more likely the goal of keeping global warming below 2 °C will be achieved.

Only time will tell who succeeds and who fails.

But we can be sure of one thing: Just like the 19th-century gold rush in the US, only companies selling the necessary equipment can be sure of making a fortune. So, what equipment are we talking about when it comes to hydrogen?

Exactly! PEM electrolyzers. And what do they depend on to work?

Precisely! Iridium. And what’s the problem with that?

Correct! Iridium is scarce and cannot be extracted in much greater quantities than today. So, with the demand for PEM electrolyzers skyrocketing, the availability of iridium is becoming a headache. The only viable solution is to reduce the amount of iridium needed in PEM electrolyzers. And who has the technology for that?

Bingo! Smoltek has both the know-how and patents for the technology, making it possible to come down to as little as one-twentieth of today’s use of iridium while maintaining efficiency.

This is, of course, a biased piece. I want you to understand that the market for Smoltek’s technology is bigger than it first appears. Much bigger. That’s my motive for compiling this catalog of applications.

Enough about that. Let’s get down to business.

Initially, we’ll embark on a high-altitude flyover to gain an overview of the land of clean hydrogen. We will then descend to a lower altitude to circle over each of the five key areas of hydrogen applications. Finally, we will execute precision low-level flybys over selected applications that stand out as particularly intriguing.

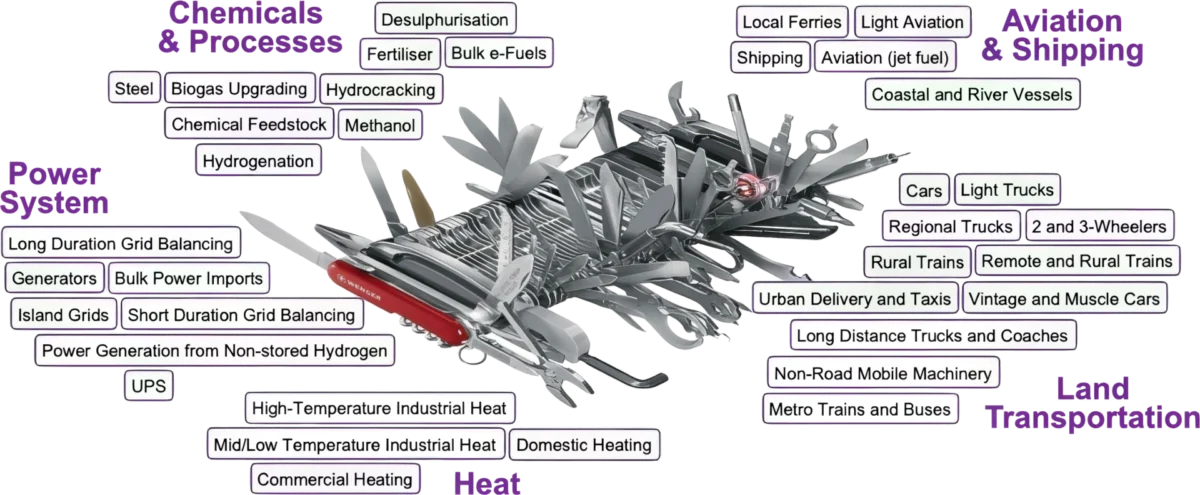

We make our first flyover at a really high altitude. What do we see? A huge Swiss army knife?! Yes, it’s called the clean hydrogen Swiss army knife. A cliché, of course. But it is an apt description of how useful clean hydrogen is. Notice the five key areas for hydrogen applications: heat, power systems, chemicals and processes, aviation and shipping, and land transport.

Satisfied?

Let’s descend to a lower altitude and fly a lap over each key area.

We are approaching the hydrogen application area of heat at a lower altitude.

Hydrogen both combusts quickly and gives off a lot of heat in the process. This can be used everywhere where heat is required: industry, commercial buildings and spaces, and homes.

High-temperature heat, above 500 °C, is used in processes such as steel making, glass making, and some chemical processes.

Mid-temperature heat, between 150 and 500 °C, is used for various industrial processes, including drying, steam production, and some chemical reactions.

Low-temperature heat, below 150 °C, is often used for heating in buildings and greenhouses and for processes such as cooking, pasteurization, and some drying.

Simply put, clean hydrogen can be used as a fossil-free fuel in industrial furnaces instead of natural gas, coal, or oil.

Our flight continues to power systems, an interesting application area for hydrogen.

As a Smoltek investor (or soon to be, I hope), you know that electricity can be turned into hydrogen through electrolyzers. You also probably know that hydrogen can be converted back into electricity. There are two main ways to do this.

The most well-known way is via fuel cells. This process essentially reverses what happens in a PEM electrolyzer. Hydrogen gas splits at the PEM; protons pass through while electrons are forced to take a detour through an external circuit, generating electricity. On the other side, they recombine with oxygen to form water. Pretty clever, right?

But there is a much simpler way: a regular gas turbine. In simple terms, a gas turbine can be described as a jet engine where fuel (hydrogen in our case) is burned, and the jet stream causes a power turbine to spin. The rotation of the turbine is propagated via a shaft to an electric generator. Out comes electricity. Ta-da!

The ability to convert electricity to hydrogen and back to electricity opens up many exciting applications. Basically, they all involve storing electrical energy as clean hydrogen for a short or long period. Short-term storage can be used to balance the electricity grid. Longer-term storage can be used to capture excess energy from sunny or windy days to feed into the grid when the sun is not shining and the wind is not blowing. Alternatively, hydrogen can be used as a fossil-free fuel in backup power plants during cold winter days.

Our flight has now reached the perhaps least known and least talked about application area for clean hydrogen: Replacing the dirty hydrogen, known as gray, brown, and black hydrogen, with clean hydrogen, known as green hydrogen. (Wondering about the colors? See our technical brief on the colors of hydrogen.)

Chemical and process industries use huge amounts of hydrogen every day. One of the biggest uses is the production of life-saving fertilizer, but there are many more.

More than 95 percent of the hydrogen used in the industry comes from natural gas converted into hydrogen with huge amounts of CO2 as a by-product. A small fraction of this CO2 is captured and tucked away in the ground or used for something better. However, an overwhelming amount is emitted directly into the atmosphere, where it contributes to the greenhouse effect.

To meet the goal of stopping global warming at 2° C, virtually all of this hydrogen must be produced by electrolyzers fed with fossil-free electricity. This is a huge but often forgotten market for clean hydrogen.

The icing on the cake, if the expression is allowed in this dire context, is the emergence of new industrial applications for clean hydrogen. Most notable are steel mills, whose polluting processes can be replaced by newer and cleaner ones using green hydrogen.

With a sense of hope, we leave the industry behind and approach our own airspace: transportation by air and sea.

When it comes to light aircraft and small boats, batteries may have a future. But as soon as we talk about planes for more than one or two people and boats that transport people and goods over long distances, batteries become impractical. These applications would require batteries that take up far too much valuable space and weigh way too much.

Since I am singing the praises of hydrogen (obviously), you now anticipate that I will say that clean hydrogen is the solution to all pollution from aviation and shipping. Right?

Gotcha!

Clean hydrogen is not the solution. Not directly, that is.

Although hydrogen has a very high energy density by weight (approximately three times the energy of jet fuel or diesel), it has a very low energy density by volume (approximately one-sixth the energy of jet fuel or diesel at 200 bar pressure). This means that gas tanks to propel airplanes and ships would take up far too much space.

The volume can be reduced by cooling the hydrogen to a liquid state. However, hydrogen only becomes liquid at −253 °C. That’s only 20 °C above absolute zero! Safely keeping the gas that cold is tricky. Moreover, it would require a lot of energy, which means that even more fuel would have to be transported. In the end, the reward for all the trouble is limited. Liquid hydrogen still has a very low energy density per volume (about a quarter of the energy in jet fuel or diesel).

So, what’s the solution?

Marine engines are tough buggers that can run on almost anything that burns. So, the best solution for them is to replace diesel or crude oil with e‑fuel or clean ammonia. As you can read in the article on e‑fuel and fertilizers, these fuels can be produced from clean hydrogen.

Aircraft engines are more delicate creatures. But again, e‑fuel is the solution in the form of e‑jetfuel.

Finally, we have arrived at the last application area for clean hydrogen: land transportation.

It is a vast field spanning everything from excavators, bulldozers, and backhoe loaders through taxis, parcel delivery, and service vans to buses, trains, and trucks. But none of this is likely to be what the Joneses think of when talking about uses of hydrogen for land transportation.

Ask anyone around you, and the chances are pretty good that they will mention hydrogen-fueled cars. If they can specify what they mean, they are almost certainly talking about fuel-cell cars. I think it’s safe to say that the fuel cell car is the poster child for hydrogen. Don’t you agree?

A fuel cell converts hydrogen from a tank and oxygen from an air intake into electricity and water. In a fuel cell car, this electricity powers electric motors. So, a fuel cell car is actually an electric car where the battery has been replaced by fuel cells. The biggest proponents of this approach are Toyota, BMW, Hyundai, Honda, Jaguar Land Rover, Pininfarina, Riversimple, and Hyperion Motors. (I hope I didn’t forget anyone.)

But why overcomplicate things? Why not directly fuel the good old internal combustion engine, found in all gasoline and diesel vehicles, with hydrogen? After all, hydrogen is highly combustible, as evidenced by the infamous Hindenburg disaster. The only thing that needs to be done is to make the engine more resistant to higher temperatures and greater forces. Some car manufacturers seem to agree. Honda, Kawasaki, Suzuki, Toyota, and Yamaha are all exploring this route.

We have now completed two overflights of the landscape with clean hydrogen applications. The first was a quick overview at a high altitude. The second flight was at a lower altitude and gave us a good opportunity to see all possible areas of use for clean hydrogen. Now it’s time for some flybys. We can’t take a closer look at all the applications; there are too many. But we’ll have time for a few anyway. So let’s begin one last lap to flyby some of the more intriguing application areas.

We start with the cement industry, which is an example of high-temperature industrial heat.

To produce cement, the cement industry heats limestone, clay, and minerals in rotary kilns to 1,450 °C. The resulting clinker is then ground into a fine powder and mixed with gypsum.

The heating comes at a high climate toll. Approximately 1 billion tons of CO2 are emitted annually when the kilns are heated with coal, oil, and natural gas. On top of that, comes additional 1.5 billion tons of carbon dioxide inevitably produced by the chemical reaction that occurs when limestone (CaCO3) is reduced to calcium oxide (CaO) in the kilns. Together, the cement industry’s carbon footprint accounts for almost 7% of the world’s carbon emissions.

Clean hydrogen can be used together with biomass to completely decarbonize the heating. The reason why they want to mix biomass has something to do with the shape of the flames. Don’t ask.

But what to do with 1.5 billion captured CO2? One idea the cement industry is considering is to use it in the production of e‑fuel – which, as you know, also requires clean hydrogen.

As we head towards the next flyby, we ask ourselves how difficult it can be to maintain a power system? Damn hard if you ask anyone with knowledge about it. The difficulty lies in ensuring that electric power plants feed into the grid exactly as many electrons as businesses and households take out of the grid – at any given moment, 24 hours a day, 7 days a week. Keeping this balance is called grid balancing.

If there is an imbalance between supply and demand, generators absorb extra energy by spinning faster or produce more energy by spinning slower. However, since the rotation speed also controls the frequency of the grid (ideally 50 HZ or 60 Hz), this regulation leads to an increase or decrease in frequency.

Only minor deviations are allowed to protect electrical equipment from being damaged. Therefore, electricity production must also be planned so that more electricity is produced when demand is expected to be high (for instance, during the day), and less electricity is produced when demand is expected to be low (for instance, at night).

But renewable electricity is not so easy to plan.

The sun rises and sets every day and plays peek-a-boo behind clouds in between. And the only constant about the wind is that its strength is ever-changing. That’s why it’s common for wind farm owners, for example, to be paid to shut down their wind turbines when the wind blows. Not what you expected, huh?

A more efficient approach is to have solar panels, or wind turbines generate electricity when possible and use any excess electricity to create hydrogen using a PEM electrolyzer. This hydrogen is stored until there’s a higher demand for electricity than what the solar or wind farm can supply. At that point, the stored hydrogen is turned back into electricity using fuel cells or gas turbines.

A related use for clean hydrogen is as fuel for peaking power plants. You know, the ones that are dormant most of the time but are started up on peak demand, like cold winter mornings, for example. These plants often run on coal, oil, or natural gas, leading to carbon dioxide emissions. An alternative is to use clean hydrogen as fuel. This hydrogen can be produced by an on-site PEM electrolyzer that gets its electricity from solar cells or a wind turbine on the roof.

Next, we set the course for areas of application in chemicals and processes, where one of the more notable and promising applications is steel production.

Global steel production results in the release of 3.7 billion tons of carbon dioxide into the atmosphere. This is more than 10% of all carbon dioxide emitted by human activity. A figure that definitely needs to come down if we are to meet the 2 °C climate target.

Carbon dioxide emissions in steel production mainly come from two sources. First, coal, oil, and natural gas are used to heat blast furnaces. Second, and more significantly, coal is added to the furnaces to create carbon monoxide, which reacts with iron ore, specifically hematite (Fe2O3) and magnetite (Fe3O4), converting it into pig iron.

The good news is that hydrogen can replace coal in the process of reducing iron ore to pig iron. It’s currently being tested in several sites inSweden, Germany, Spain, South Korea, UK, Norway, and Austria.

By using clean hydrogen both to heaten the furnaces and to replace coal in the reduction process, it is possible to completely reduce the carbon dioxide emissions from steel making and thus produce green steel.

We steer our flight towards the ocean. On the horizon, we see cargo ships with sooty diesel exhaust trailing behind them like long, dirty tails. The maritime industry is a significant contributor to carbon emissions, with long-distance cargo ships releasing about 1 billion tons of CO2 annually. For these vessels, batteries are impractical due to their size and weight, making green hydrogen a key part of the solution.

However, using hydrogen directly in internal combustion engines poses challenges due to its low volumetric energy density, meaning it requires too much space. This makes it unlikely for large ocean-going ships to adopt hydrogen combustion engines or fuel cell-powered electric motors. The most promising alternatives are synthetic fuels. The contenders are e‑methanol, e‑methane, and clean ammonia.

E‑methanol and e‑methane, on the one hand, are produced by combining carbon dioxide and clean hydrogen. In the best case, the carbon dioxide is captured from the air, which is climate neutral; in the worst case, carbon dioxide is captured on its way to be released, which only postpones the release.

Clean ammonia, on the other hand, is produced by combining nitrogen taken directly from the air with clean hydrogen.

So far, e‑methanol has taken the lead. Both e‑methanol production facilities are being built, such as FlagshipONE, which I talked about in the post on e‑fuel, and e‑methanol-powered ships, such as the Laura Maersk, which will be launched in 2023.

However, clean ammonia is the new and cool kid on the block. It has recently gained a lot of traction in maritime circles and is being actively promoted around the globe.

The construction of clean ammonia production facilities is underway in several countries, including Norway, the Netherlands, South Korea, Chile, and Japan. Companies like MAN Energy Solutions and Mitsubishi Heavy Industries are leading the development of innovative ammonia-powered engines. In Norway, the first container ship powered by clean ammonia, Yara Eyde, will be launched in 2026.

E‑methanol, e‑methane, and clean ammonia can all be used by ferries, coastal freighters, riverboats, tugs, barges, and other vessels operating over shorter distances and time. But for these vessels, it’s perfectly reasonable to use hydrogen directly to propel them. The predominant approach is fuel cells that convert hydrogen into electricity to power electric motors.

An example of this approach is HEAVENN in the Northern Netherlands, which aims to build a dedicated hydrogen transport infrastructure including pipelines, storage facilities, and refueling/bunkering points for various applications, including maritime shipping.

On the vessel side, MF Hydra serves as a notable example, being the world’s first ferry powered by hydrogen. Delivered in 2021, this 82.4‑meter-long ferry can carry up to 80 vehicles and 300 passengers, cruising at a speed of 9 knots. It’s operated by the Norwegian company Norled.

We fly in over land again and come to the last application area for hydrogen: land transportation and non-road mobile machinery. There are various applications here. Let’s flyby some of them.

Hydrogen-powered buses, mainly driven by electric motors using electricity from fuel cells but also internal combustion engines running on hydrogen, have been on the agenda for decades. Many cities, including London, Tokyo, and Los Angeles, have integrated hydrogen-powered buses for public transportation into their fleets. The appeal lies in their zero emissions, longer range, and quick refueling times compared to battery electric buses.

The French train manufacturer Alstom is investing heavily in hydrogen trains. They develop, manufacture, and sell hydrogen-powered trains for intercity and regional service. The trains are called Coradia iLint and have been evaluated in several countries.

Alstrom is far from alone. Close behind are Siemens, CRRC, Toyota, Hyundai Rotem, Ballard Power Systems, and Stadler Rail.

There are several countries and railway companies that are hot on their heels, including the USA, Japan, United Kingdom, Japan, and India, and even more are thinking about getting hydrogen-powered trains.

But when it comes to adopting hydrogen-powered trains, Germany has taken the lead. In September 2018, Germany’s Lower Saxony launched the world’s first hydrogen-powered passenger train for commercial use. Then, in August 2022, Lower Saxony introduced the first railway line run entirely by hydrogen-powered trains in Bremervörde.

Driving a car in Paris requires a Crit’Air vignette – a windshield sticker showing how environmentally friendly the car is with numbers from 0 (zero emissions) to 5 (most polluting). From 2024, only vehicles with Crit’Air 0 or 1 vignettes are allowed in Paris. From 2030, Crit’Air 0 will be required. These tough requirements have spurred the Parisian taxi sector’s interest in hydrogen cars.

Hype describes itself as the first zero-emission mobility platform. We mere mortals call them a taxi company. In 2023, they had 550 hydrogen taxis operating in Paris. By the end of 2024, they plan to have 1,500 hydrogen taxis.

In 2019, Hype, Toyota, Air Liquide, and Idex joined forces to form HystCo with the aim of building a network of filling stations for hydrogen and mobility-related applications. The latter has so far manifested itself in the possibility of professionals leasing a car or van running on hydrogen. Since its creation, more companies have joined and pumped millions of euros into the company. By the end of 2023, HysetCo will distribute more than 23 tons of hydrogen per month to its customers and manage a fleet of more than 550 hydrogen vehicles.

Both Hype and HysetCo have ambitions to rapidly expand their operations throughout France.

From taxis to parcel delivery, it’s a short step. From an operational perspective, they are very similar. In both cases, the vehicles typically drive 400–600 kilometers per day and need to count the time to refuel in minutes instead of hours. Therefore, hydrogen is an interesting alternative to batteries as these sectors move away from gasoline and diesel to carbon-free alternatives.

But unlike taxis, which are well on their way, most parcel delivery companies are still in the parking lot, with only a few small-scale pilots running in the field. One example is FedEx, which has started a trial of a hydrogen-powered vehicle in its pickup and delivery operations in Utrecht, the Netherlands.

The same is true for service vans. But it is only a matter of time before green hydrogen fuels every van or light commercial vehicle (LCV), as it is called in industry lingo. At least that’s the belief of First Hydrogen – a Canadian-British start-up that is developing and manufacturing its own light commercial vehicle and setting up a network of refueling stations.

From the many but short distances covered by parcel delivery pickups, we enter the realm of heavy trucks. They can be divided into line-haul and long-haul. The difference lies in how far they drive. Line-haul refers to transport to destinations such as ports or logistics centers, usually within one day, while long-haul refers to longer transports that take days or weeks to complete. For both applications, hydrogen is on the rise.

In Switzerland, for example, 47 heavy trucks by Hyundai are in use by logistics, distribution, and retail fleet operators. These trucks are named XCIENT Fuel Cell. As the name suggests, they have electric motors powered by hydrogen fuel cells.

H2Haul is an EU-funded project that aims to run 16 long-haul heavy-duty fuel cell trucks for more than one million kilometers under normal commercial conditions to demonstrate high reliability. The project also includes hydrogen refueling infrastructure. Users include BMW in Germany, Carrefour in France, Coop in Switzerland, and Colruyt Group in Belgium.

HyTrucks is a consortium started by Air Liquide, DATS 24, and the ports of Rotterdam, Antwerp, and Duisburg. Today, it consists of over 70 companies and countries. The consortium is based on two simple ideas: First, the transition from a diesel ecosystem to a hydrogen ecosystem can only succeed if all relevant parties are involved. Second, hydrogen is very suitable as an energy carrier for heavy-duty transportation. HyTrucks wants at least a thousand heavy-duty hydrogen trucks on the road by 2025. At the same time, they also want to have at least 25 operational hydrogen refueling stations. The trucks will be deployed mainly in the triangle between three of the major logistics hotspots in Western Europe – the ports of Rotterdam, Antwerp, and Duisburg – as well as in Germany, Luxembourg, and France.

Non-road mobile machinery (NRMM) is a bit of a mouthful. The term covers all types of work machines, including excavators, cranes, forklifts, bulldozers, harvesters, backhoe loaders, tractors, and plow trucks.

Hydrogen for direct combustion, fuel cells, or in the form of e‑fuel is very attractive to use in NRMM for several reasons. Beyond the obvious one that they don’t contribute to the greenhouse effect and have quick refueling times compared to a battery, there are two major benefits specific to this category of vehicles.

First of all, they don’t pollute where they operate. This is particularly desirable when used in confined spaces, such as warehouses or mines, but is also desirable in agriculture and sensitive natural areas. (Notice that e‑fuel doesn’t have this benefit; the combustion of e‑fuel releases the CO2 captured during production.)

Second, with its ability to be transported and stored, hydrogen is a viable option for remote and off-grid operations where electricity is not available to charge batteries.

Several well-known construction equipment manufacturers, including Volvo Construction Equipment, Hyzon Motors, and Liebherr, are investing heavily in hydrogen, either in the form of fuel cells or hydrogen-powered internal combustion engines. However, the company that has made the most headlines is JCB, one of the world’s largest manufacturers of construction equipment. They have developed a backhoe loader with a hydrogen combustion engine and a fuel cell-powered forklift.

Oh boy. It was a long flight, but now we have landed. It was exciting, wasn’t it? Clean hydrogen is indeed on its way. So many applications! And they all need PEM electrolyzers galore. And since we’re sitting on a key technology to enable this growth at a reasonable price, it’s hard not to think that Smoltek Hydrogen will be a success. Don’t you agree?

Your data will be handled in compliance with our privacy policy.