Sign up for our newsletter!

Your data will be handled in compliance with our privacy policy.

Your data will be handled in compliance with our privacy policy.

Technology drives the world forward. Smoltek is ready to make space for the next technological leap in the semiconductor and hydrogen industries.

Our patent-protected technology radically increases the available surface for chemical and electrical processes, enabling more compact, energy-efficient, powerful and cost-efficient products.

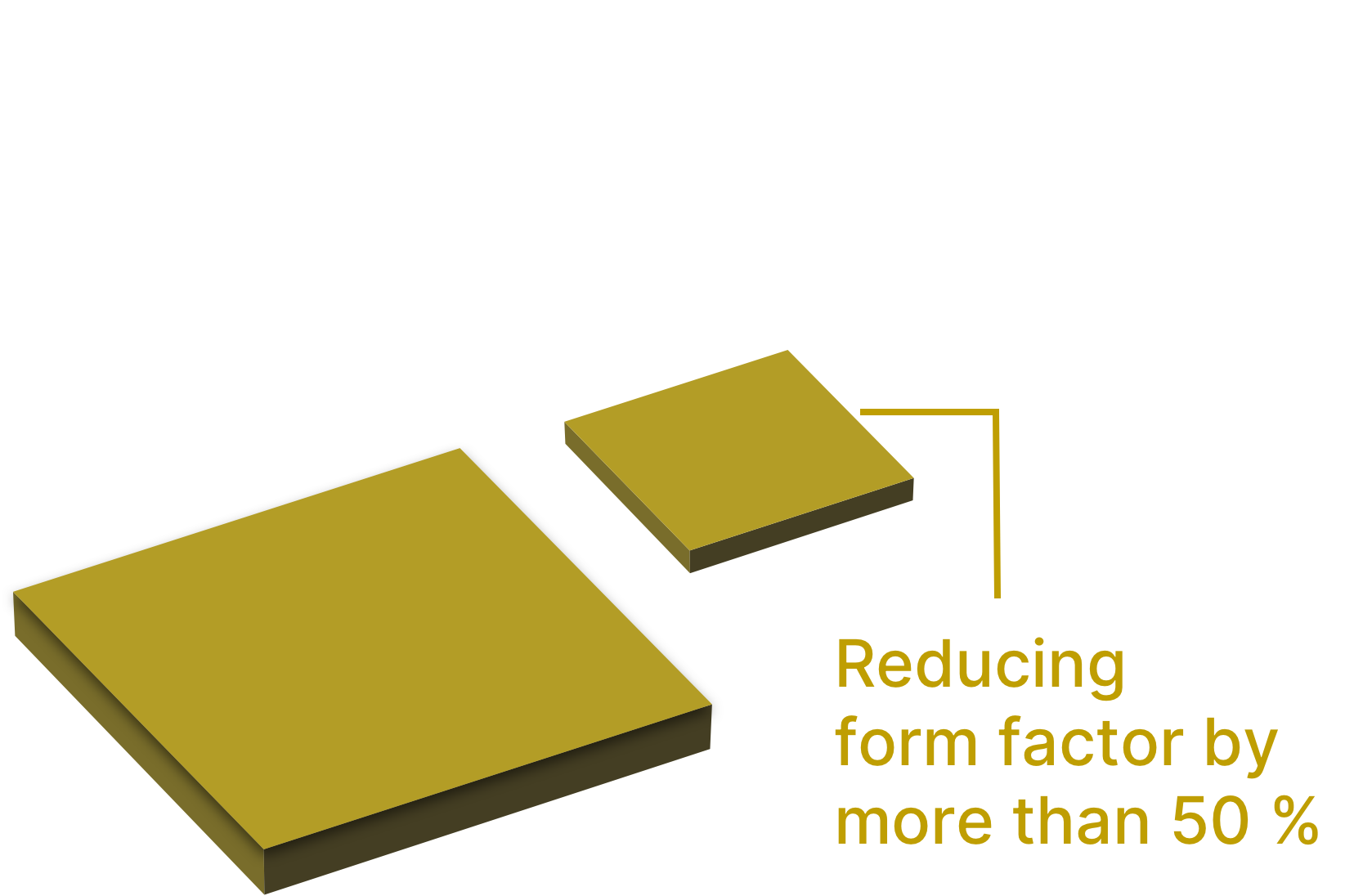

The number of transistors on microchips is doubled every second year, driven by the quest for more computing power. With our technology for ultra-thin capacitors that make space on microchips, the semiconductor industry can once again meet rising demands for higher performance.

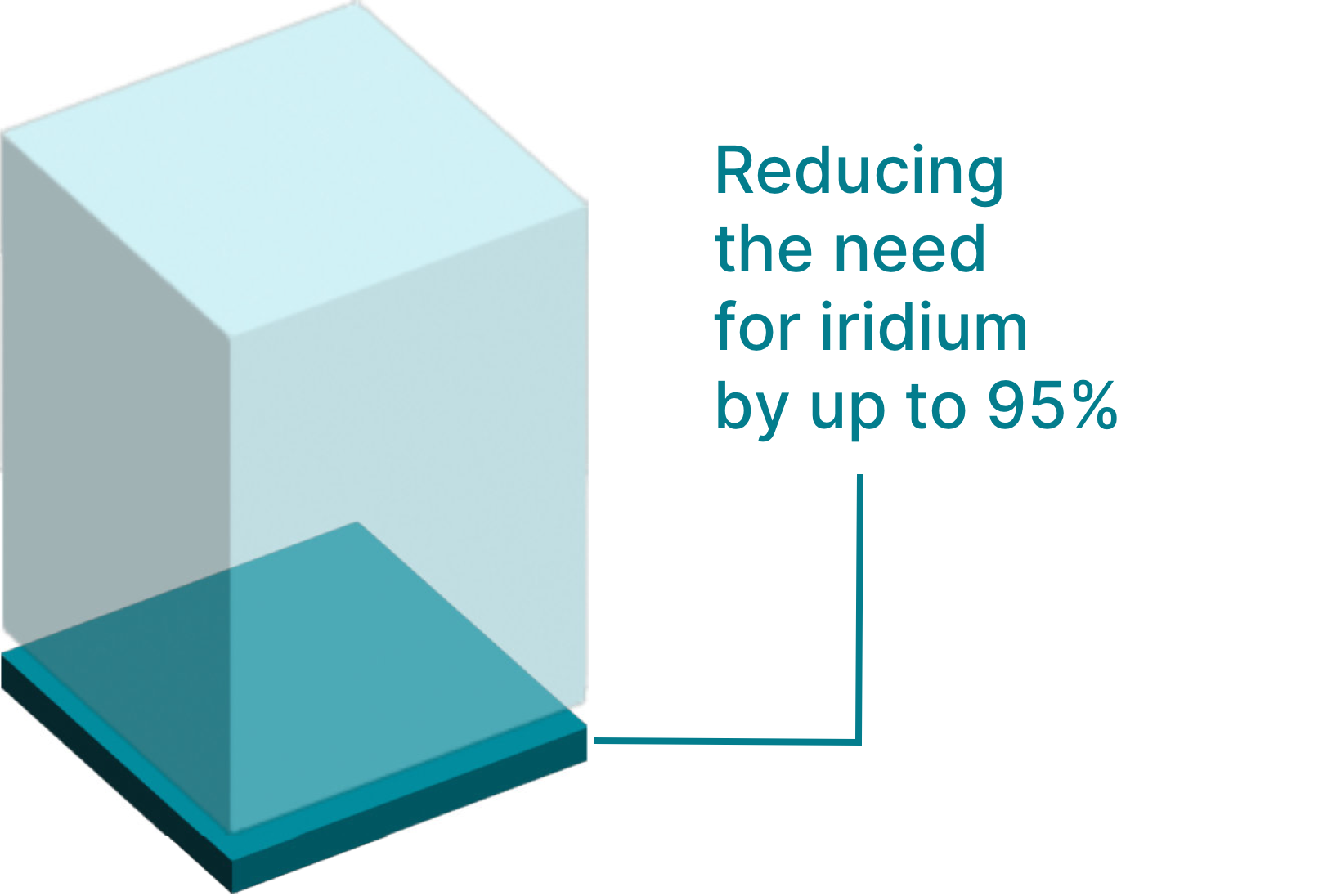

The interest in green hydrogen is taking off, but the current need for iridium drives costs, making upscaling difficult. With our technology for compact electrolyzers using a minimum of precious catalyst particles, the green hydrogen industry can turn prospects into business.

Approximately 1,000 billion semiconductors are produced worldwide annually. To understand the magnitude of the business, that number corresponds to 125 semiconductors per person and year. Modern electric cars usually contain 2,000 semiconductors.

A rapidly evolving market. In 2021, the global PEM (Proton-exchange membrane) electrolyzer market was valued at USD 737 million. This figure is expected to rise to almost USD 4,3 billion in 2027.

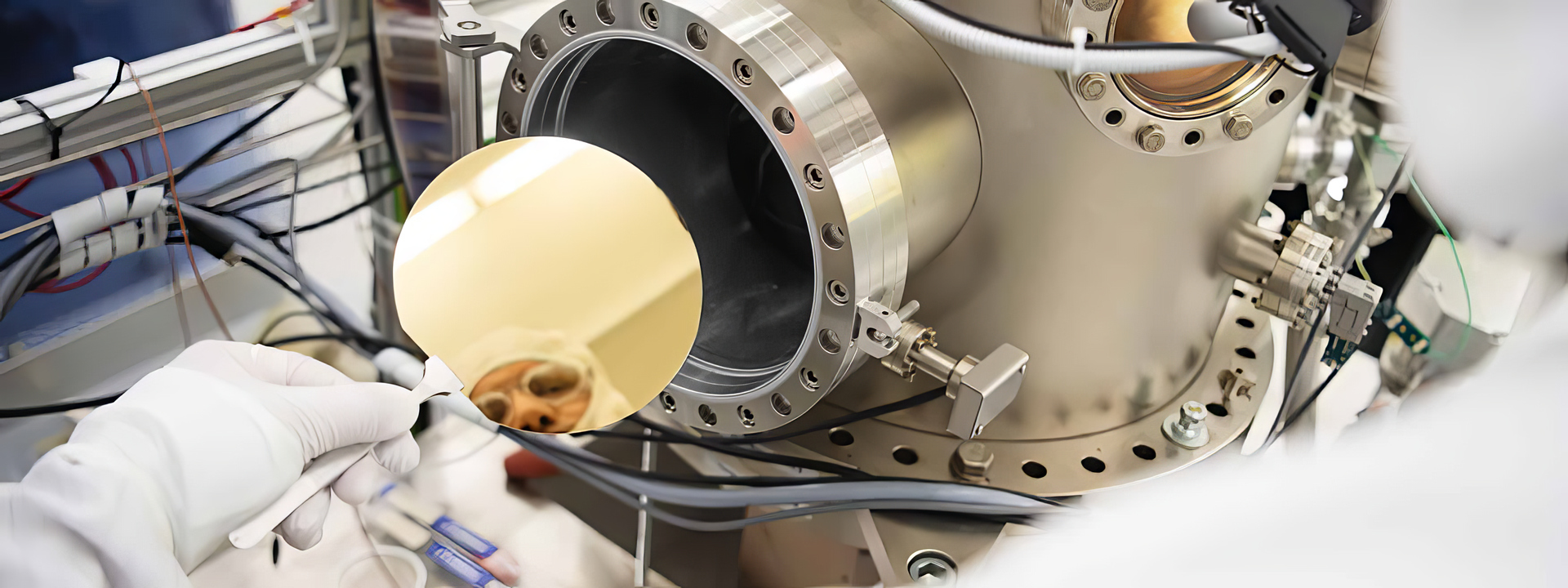

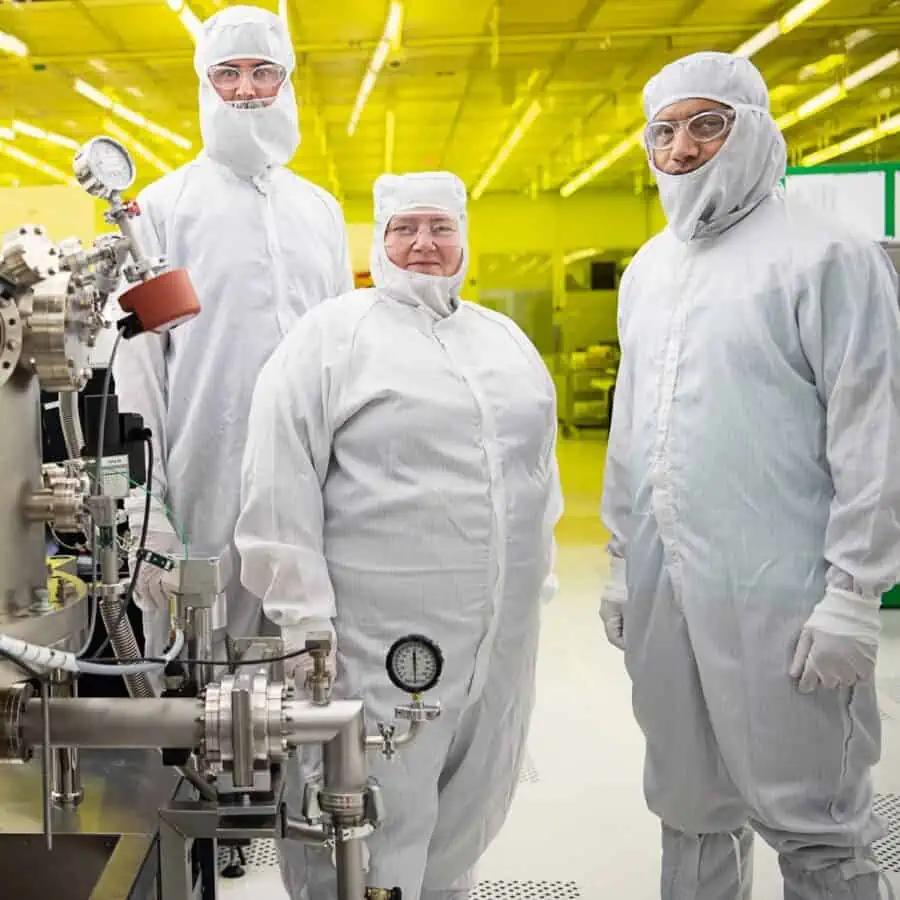

Smoltek is developing process technology and concepts for applications in order to solve advanced materials engineering problems. By pioneering carbon nanotechnology we are literally pushing the limits of what is possible in the semiconductor and hydrogen industries.

Our patent protected technology platform is based on carbon nanofibers (CNFs), which have very exciting properties, that may disrupt technical solutions where today’s materials have reached their limit of performance.

As an example, we have developed a prototype of the world’s smallest capacitor and we are developing a new cell-material with the ambition to double (or even triple) the area-efficiency of PEM water-electrolyzers.

We are scientists and engineers with a passion for nanotechnology. We are in the never-ending search of how to enhance and fabricate carbon nanostructures, with unique properties, in pre-defined patterns to enable better solutions within several industries.

Read about Smoltek

The Smoltek share is listed on Spotlight Stock Market. We are now in an industrialization phase where we focus on two sectors with enormous potential: Semiconductors and Hydrogen. We plan to begin volume production in 2024–2026. Join our journey!

Discover our share

Smoltek is on a mission to deliver disruptive solutions for the semiconductor and hydrogen industries, based on our nanotechnology platform. Does this sound interesting? Join us, and become a superstar within groundbreaking technology!

Make your moveSmoltek Semi and the Taiwanese Industrial Technology Research Institute (ITRI) have finalized the technical framework for the establishment of a pilot production line for Smoltek’s CNF-MIM capacitors at ITRI.

Qi Li and ChinJung Kuo of Smoltek Semi have met with Skytech management in Taiwan for planning of testing dummy runs for ALD deposition of Smoltek’s CNF-MIM capacitors.

Smoltek Hydrogen is attending the 247th ECS Meeting in Montréal, Canada. The event brings together the most active researchers in academia, government, and industry to engage, discuss, and innovate in the areas of electrochemistry and solid state science and related technologies.

Your data will be handled in compliance with our privacy policy.